The Role of Multiwall Polycarbonate Sheets in Energy Efficiency

Thermal Insulation Properties of Polycarbonate Roof Panels

Multiwall polycarbonate sheets offer really good thermal insulation because they come with pretty high R-values. The R-value basically measures how well something resists heat moving through it, so when numbers go up, insulation gets better too. Compared to old school glass or other standard glazing options, these polycarbonate panels pack much higher R-values, which means less heat slips through them. What does this mean practically? Buildings need less energy to keep warm in winter and cool in summer, cutting down on those monthly utility bills over time. Real world tests show these panels actually work at slowing heat movement, which is why many builders now prefer them for projects where saving energy matters most.

UV Protection and Light Diffusion for Reduced Cooling Demands

Polycarbonate sheets offer good protection against UV radiation, something that really matters when trying to keep indoor temperatures steady. These materials stop most of those harmful UV rays from getting through, so buildings don't get as hot inside. Another great thing about them is how they spread out natural light across rooms without creating harsh glare spots. This means spaces stay well lit during the day without needing extra lights turned on all the time. People who have installed these sheets report noticeable drops in their cooling bills because there's less need for air conditioning systems to work overtime, plus everyone seems happier sitting in naturally lit environments anyway.

Structural Advantages Over Traditional Glass and Acrylic

Polycarbonate sheets in multiwall form weigh much less than traditional glass or acrylic options. This makes them easier on building structures and cuts down on the power needed during installation work. What really stands out though is how tough these materials are against impacts and wear and tear. Buildings don't need constant fixing or replacing parts made from polycarbonate, so there's a big drop in ongoing maintenance costs and associated energy consumption. Architects and builders across the country have started turning to polycarbonate because it holds up well under tough weather conditions while still performing great. Many commercial buildings now feature these sheets where they need something strong yet light weight for both aesthetic appeal and practical function.

Case Study: Commercial Greenhouse Energy Savings with Clear Roofing Panels

Challenges of Conventional Greenhouse Glazing

The glass and plastic used in traditional greenhouses tend to cause real problems when it comes to keeping heat in and cutting down on energy costs. Most standard materials just don't insulate well enough, so growers end up spending extra on electricity to keep plants at the right temperature. Because of this poor performance, many operations install additional heaters and fans just to maintain stable conditions inside, which naturally drives up power bills even more. Research from agricultural engineering departments shows something pretty startling actually conventional greenhouses might be using around 30 percent more energy compared to newer models with better glazing options. These numbers make it clear why so many farmers are now looking seriously at alternative materials that can slash their energy expenses without compromising crop quality.

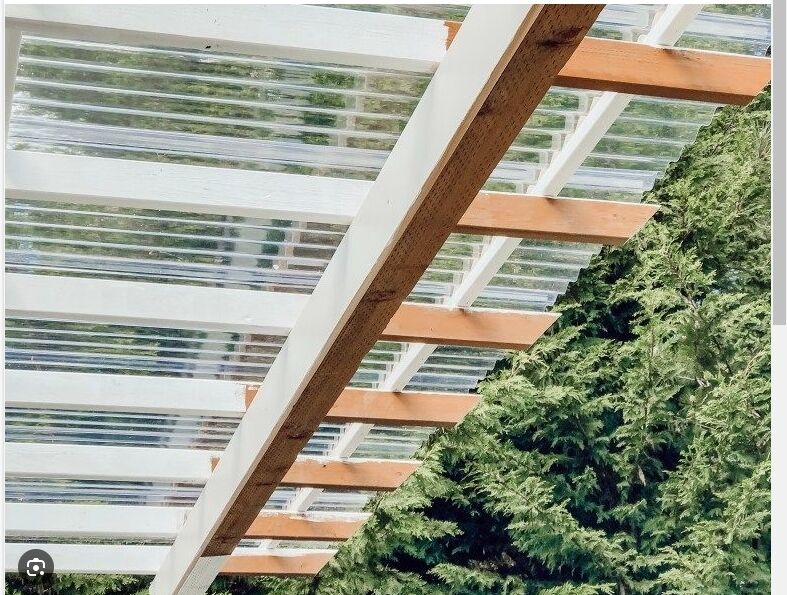

Installation of 16mm Multiwall Polycarbonate Sheets

Putting in those multiwall polycarbonate sheets for a greenhouse requires attention to a few important details if we want good light transmission and decent heat control. First things first, check that the roof framework is ready to hold those panels without putting too much strain on anything. Most pros will tell gardeners to make sure those vertical ribs are lined up right so rainwater flows off properly, not pooling somewhere it shouldn't. Also worth adding some UV protective film underneath to keep the panels from yellowing after a few seasons outside. Clear panels really make a difference in letting sunlight through all day long, which means less need for those expensive grow lights at night. Get everything installed correctly though, and the whole setup becomes way more efficient energy-wise while still keeping plants happy in their ideal climate conditions most of the time.

Quantified Reduction in Heating/Cooling Costs

Looking at what happened at GreenLife Growers after they installed multiwall polycarbonate panels tells us something interesting about energy costs in greenhouses. When they swapped out their old glass and plastic materials for these new polycarbonate sheets, they saw their heating and cooling expenses drop quite a bit. The actual numbers? Around 25% less energy used each year. That meant real money saved too – somewhere in the thousands annually, which made the upfront cost worth it pretty quickly. What stands out most is how much difference these materials make on monthly utility bills. Farmers who have switched report similar results across different climates. Energy usage just keeps going down compared to those still using traditional glazing methods, making polycarbonate panels a smart choice for anyone running a greenhouse concerned about both bottom line and environmental impact.

Retrofitting Industrial Buildings with Corrugated Plastic Roofing Alternatives

Energy Loss in Metal Roof Warehouses

Warehouses with metal roofs tend to lose a lot of energy because they don't handle heat transfer very well, which means higher bills for electricity and heating. Research indicates that around 30 percent of all energy wasted in industrial spaces comes from those metal tops, mostly since metals conduct heat so easily. Many folks forget about basic things when trying to make buildings more efficient. Poor insulation here and there, plus bad airflow design, just makes matters worse. Industry experts point out that fixing these problems and going with better roofing options can cut down on those costly energy bills significantly over time.

Comparing Multiwall vs. Corrugated Plastic Roofing Performance

Looking at how multiwall polycarbonate roofs compare to corrugated plastic options for thermal efficiency involves considering factors like UV resistance, how much upkeep they need, and how long they last before replacement becomes necessary. The layered construction of multiwall polycarbonate generally gives it the edge when it comes to keeping heat out during summer months and retaining warmth in winter conditions. But don't overlook corrugated plastic just yet – these materials actually handle UV exposure pretty well and are much simpler to install for most contractors working on site. Research comparing different materials shows both have their strengths. Some businesses might prefer one over the other based purely on what matters most to them financially speaking, whether that's cutting down on heating bills or making sure the roof lasts through multiple seasons without needing repairs.

Documented Annual Energy Consumption Improvements

There's plenty of evidence showing buildings consume less energy after installing corrugated plastic roofs, especially in factories and warehouses. Some facility managers have seen their monthly bills drop around 20 percent because this type of roofing actually insulates better than traditional options. Energy consultants who've studied these installations point out that the money saved on electricity makes the initial investment worth it much faster than expected. Most industry experts we've talked to recommend going with corrugated plastic when looking at roof replacements. They back this up with real numbers from their audits, though they'll also mention that results can vary depending on local climate conditions and how well the installation was done.

Thermal Performance in Extreme Climates: Polycarbonate vs. Traditional Materials

Snow Load Resistance and Winter Insulation Metrics

Polycarbonate roofing stands up really well against heavy snow loads and provides good insulation in cold weather conditions, beating out many traditional roofing options. The reason behind this durability lies in the material's impressive tensile strength properties that let it hold up under significant weight without cracking or shattering. When we look at engineering data on insulation values, polycarbonate sheets actually perform better thermally than common alternatives like glass panels or metal roofs. Some local building regulations specify minimum R-values for insulation, and polycarbonate typically meets these requirements with room to spare, helping buildings stay warmer while cutting down on heating costs during those brutal winter periods. Architects and engineers often refer to industry standards like those from ASHRAE when specifying materials, and polycarbonate generally checks all the boxes for snow load resistance according to these established benchmarks.

Tropical Climate UV Reflection Case Analysis

Polycarbonate roofing really works well in hot, sunny climates because it reflects a lot of UV light, making buildings much more energy efficient. When builders use these materials, they typically see lower cooling bills since the roof doesn't absorb so much heat from those intense sun rays. We've seen this work in places like Southeast Asia and parts of Africa where temperatures can get extremely high during certain seasons. The sheets actually cut down on indoor temps by several degrees, which means people spend way less money running their air conditioners all day long. For anyone looking at building or renovating in a warm climate, this reflective property should be one of the main factors when choosing roofing materials.

10-Year Durability Impact on Energy Maintenance Costs

Polycarbonate roofing stands out for lasting durability that really cuts down on maintenance and repair expenses over time, especially when looking at a ten year period. Traditional roofing materials tend to need replacing quite often, but polycarbonate sheets actually hold up well without losing their structural integrity, so there's less money spent fixing things later. Industry data shows that buildings with polycarbonate roofs just don't need replacing as frequently compared to other options, and this translates into real dollar savings for property owners. One recent market report tracked these cost differences across multiple building types and found that the reduced need for repairs makes polycarbonate a smart investment choice. For homes and businesses alike, this material offers both economic advantages and environmental benefits that keep making sense year after year.

Optimizing Installation Techniques for Maximum Energy Savings

Sealing Methods for Air Leakage Prevention

Getting the most out of energy savings with polycarbonate roofing really comes down to good sealing practices that stop air from leaking through. The market has seen all sorts of sealing approaches over time designed to keep heat where it belongs inside those polycarbonate roof systems so they work as intended. Take rubber or silicone gaskets for example. When installed properly, these materials do wonders at cutting down on unwanted air getting in through gaps. Field tests show that even basic installations benefit from these materials whether the roof is flat or has those wave patterns we see so often. Most professionals will tell anyone who asks that regular inspections are a must too. After storms or heavy winds hit, checking those seals makes sense because damage happens more than people realize. All these steps together preserve the insulating qualities that make polycarbonate such a smart option compared to older building materials while still saving money on heating costs.

Slope and Orientation Considerations

How we position polycarbonate roofing affects its ability to save energy significantly. When installed correctly, these roofs let in more natural light during the day, cutting down on electricity needed for lighting inside buildings. Studies show that steeper slopes facing south tend to capture more sunlight, something that matters a lot in colder regions where heating costs are high. Sustainable architecture experts back this up too, pointing to real world examples where buildings saved money on their energy bills. Take a small change in roof angle tailored to local sun patterns, and some buildings have seen around 10 percent better performance in terms of energy collection. Getting the slope right and choosing the proper direction isn't just about looks anymore; it makes a real difference when trying to create buildings that consume less power overall.

Complementary Technologies for Synergistic Efficiency

Looking at other tech options alongside polycarbonate roofs can really improve how well they save energy. Reflective coatings work great because they help send sunlight back out instead of letting it heat up the building inside. And when smart thermostats get added to these roofs, buildings actually manage their energy better overall. The whole system lets temperature adjustments happen automatically based on what's needed at any given moment, which cuts down on wasted power. We've seen this work in real life too - some buildings now have solar panels installed right on top of their polycarbonate roofs. These approaches make those plastic roofs perform much better than before while opening up new ways to cut energy costs across contemporary building designs.

Table of Contents

- The Role of Multiwall Polycarbonate Sheets in Energy Efficiency

- Case Study: Commercial Greenhouse Energy Savings with Clear Roofing Panels

- Retrofitting Industrial Buildings with Corrugated Plastic Roofing Alternatives

- Thermal Performance in Extreme Climates: Polycarbonate vs. Traditional Materials

- Optimizing Installation Techniques for Maximum Energy Savings