Benefits of Polycarbonate Roof Panels

Durability and Impact Resistance

Polycarbonate roof panels really shine when it comes to lasting power and ability to take hits without breaking, which makes them far better than regular glass options. They hold up against pretty much anything Mother Nature throws at them including strong winds, big hail stones, and temperature extremes that would crack ordinary materials. Most last well past 15 years before needing replacement. Tests actually show these panels can handle impacts around 200 times stronger than standard glass can manage. The bottom line is this toughness means fewer repairs down the road and buildings stay protected much longer than they would with traditional roofing materials.

UV Protection and Light Transmission

Polycarbonate panels block almost all harmful UV rays, with some models stopping as much as 99.9% of those damaging sun particles. This kind of protection really matters when it comes to keeping both plants healthy and workers safe inside greenhouses where intense sunlight can be problematic. What makes these panels stand out though is how well they let visible light through while still filtering out the bad stuff. Most growers know that plants need plenty of daylight but too much UV radiation actually harms them over time. The way polycarbonate manages this delicate balance between light transmission and UV protection explains why so many modern greenhouses have switched to these panels instead of traditional glass alternatives.

Thermal Insulation for Greenhouses

Polycarbonate roof panels with their multiwall construction provide pretty good thermal insulation, which is really important when trying to keep greenhouse temperatures steady throughout the year. The way these panels regulate temperature actually cuts down on the money spent on heating systems, making them a greener choice for managing greenhouses. Studies have shown something interesting too - polycarbonate materials can reduce heat loss by around half when compared to old fashioned glass options. For gardeners or farmers looking to save on bills while being kinder to the environment, switching to multiwall polycarbonate sheets seems like a smart move for most greenhouse setups.

Types of Polycarbonate Roofing Sheets

Corrugated Polycarbonate Sheets

When it comes to roofing materials, corrugated polycarbonate sheets stand out because they're light on weight but heavy on benefits. The installation is pretty simple too, which saves time and labor costs during construction. What makes these sheets special is their ribbed design that adds structural integrity without blocking natural light from passing through. Homeowners and business owners alike find them budget friendly for various roof applications. From backyard sheds to large warehouse structures, these versatile panels adapt well to different architectural requirements while still keeping maintenance expenses low over time.

Multiwall Polycarbonate Panels

Multiwall polycarbonate panels stand out because of their great insulation qualities, which makes them really good for buildings that need to save energy. The way these panels are built with multiple layers creates tiny pockets of trapped air, and this helps keep heat from moving through the material. Builders can actually pick different thickness options depending on what kind of climate they're dealing with locally. For projects where keeping things warm or cool matters a lot while still wanting something light enough to handle easily, multiwall panels hit the sweet spot between staying strong structurally and cutting down on heating costs over time.

Solid vs. Hollow Core Options

Picking between solid and hollow core polycarbonate sheets really comes down to what the job actually requires. Solid sheets pack quite a punch when it comes to strength and transparency, which makes them great for things that need protection against impact or harsh conditions. For instance, security windows often use these because they won't crack easily. Hollow core versions are totally different though. They're lighter on the wallet and the structure, bend better without breaking, and insulate much better than their solid counterparts. Gardeners know this well since most greenhouse builders swear by hollow cores for keeping plants warm while letting light through. At the end of the day, whether someone goes solid or hollow just boils down to how much strength versus weight savings matters for whatever application they have in mind.

Essential Tools and Materials for Installation

Cutting and Fastening Tools

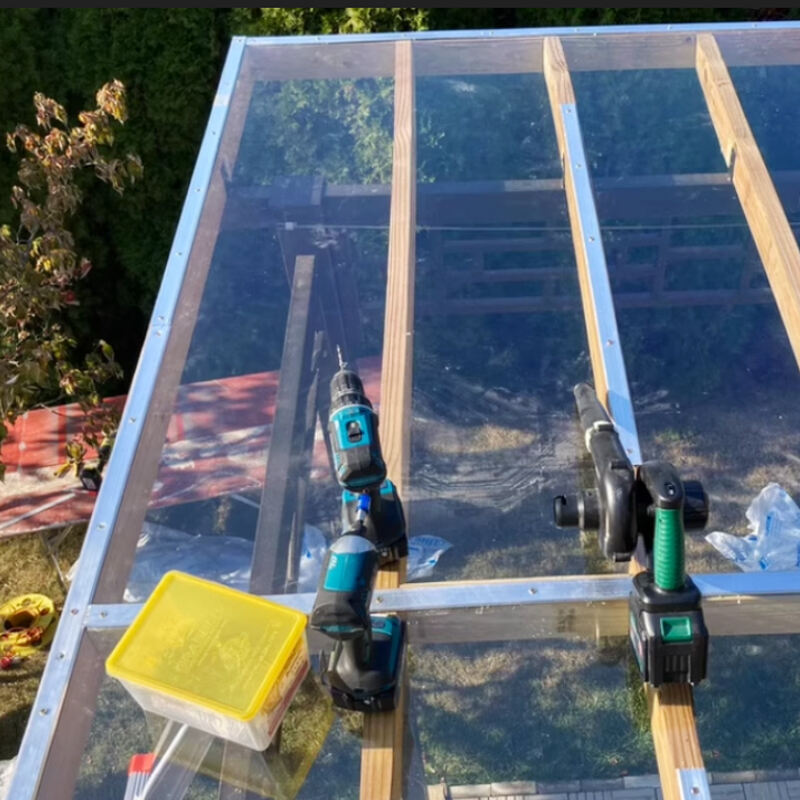

Installing polycarbonate roofing sheets requires precise cutting and securing to ensure durability and performance. The key tools necessary for installation include:

- Circular Saw with Fine-Toothed Blade: This tool is essential for accurate cuts, preventing damage to the sheets.

- Stainless Steel Screws and Bolts: Opt for these fasteners to ensure long-lasting durability and resistance to corrosion.

- Recommended Tools:

- Circular saw

- Drill

- Tape measure

- Screwdriver

By utilizing these tools, we ensure the sheets are properly cut and fastened, enhancing the structural integrity of the installation. The choice of stainless steel screws and bolts is particularly crucial for avoiding corrosion, thereby extending the life of the roofing.

Sealants and Anti-Dust Tape

Maintaining the integrity and longevity of polycarbonate roofing sheets demands the use of high-quality sealants and anti-dust tape. These materials are vital for optimal performance:

- High-Quality Sealants: These prevent water ingress, a critical factor in prolonging the lifespan of the roofing.

- Anti-Dust Tape: This aids in keeping panels clean during installation, which is crucial for maintaining UV protection.

- Selecting Sealants: Consider weather conditions and specific panel applications when selecting the right sealants.

Using appropriate sealants ensures that the roofing sheets are not only waterproof but also protected against dust and debris, which could compromise their UV protection features.

Flashing and Capping Requirements

Proper installation of flashing and capping is fundamental in maintaining the integrity and aesthetics of the polycarbonate roof. These components serve several important purposes:

- Flashing: This redirects water away from joints, preventing leaks that could damage the roofing structure.

- Capping: Protects against elements while providing a finished look to the roof.

- Structural Integrity: The combined system of flashing and capping plays a critical role in enhancing the roof's structural integrity.

Flashing and capping are essential for safeguarding the roof against the elements, ensuring it remains both functional and visually appealing over time. These installations not only prevent leaks but also contribute to the overall durability of the roofing system.

Step-by-Step Installation Process

Getting those polycarbonate roof panels installed right starts with good measurements and proper prep work on the roof frame. First things first, take careful measurements of the entire roof frame space. A little mistake here can cause big headaches later when trying to fit everything together properly. Once measurements are done, check out the frame itself. Make sure it's structurally sound and capable of holding up under the weight of the panels. Clean off any dirt, debris or moisture from the surface areas where panels will sit. Nobody wants water getting trapped underneath because of poor preparation. Many folks find it really useful to create a step-by-step list before starting. Something like marking where each panel goes, double checking alignment points, and keeping track of fasteners helps avoid missing important details during installation.

Proper handling and cutting methods are really important if we want to keep polycarbonate sheets in good condition. These materials need gentle treatment during transport and storage to prevent those annoying scratches or dents that can weaken them over time. How we cut these sheets depends largely on how thick they are. For the thinner ones, scoring works pretty well most of the time. But when dealing with something substantial like those greenhouse panels, a saw tends to do the job better. Following standard cutting practices matters because it creates nice straight edges that actually fit properly into the roof framework. Nobody wants gaps or wobbly pieces ruining what should be a neat looking installation at the end of the day.

Leaving space between polycarbonate sheets during installation helps avoid problems such as warping or buckling later on. Most installers know they need to factor in thermal expansion when working with these materials. The general rule of thumb from manufacturers suggests about a quarter inch gap for every ten feet of panel length. Getting this right makes all the difference for the long term stability of the roof structure. Proper spacing prevents stress buildup that can lead to premature failure, especially when temperatures swing back and forth throughout the seasons.

Getting those joints and edges sealed right means using good quality sealants that actually create watertight connections between the sheets. This stops water from sneaking in and helps extend how long the roof lasts before needing repairs. When done properly, sealing also boosts insulation so the building stays warmer in winter and cooler in summer while protecting against rain, snow, and UV damage. Anyone who wants their installation to last should plan ahead when applying sealant, looking for spots where problems might develop later on. The extra time spent now prevents costly fixes down the road. With proper sealing techniques applied correctly, most polycarbonate roofs can stay leak free for years without major issues.

Maintenance and Common Mistakes to Avoid

Cleaning Without Damaging UV Coating

Keeping the UV coating intact on those polycarbonate roof panels really matters if we want them to last. The wrong cleaner can ruin everything, so stick to gentle stuff that won't scratch the surface. Most folks find that cleaning twice a year works pretty well for keeping dirt and grime from building up, which helps avoid those annoying UV degradation issues. Industry pros generally back this approach since it keeps the panels looking good while maintaining their performance capabilities. And let's face it, nobody wants their roof panels turning yellow or cracking early just because they skipped a cleaning session now and then.

Addressing Thermal Expansion Issues

Changes in temperature really take a toll on polycarbonate sheets, which means regular checkups and maintenance are pretty much unavoidable. Keeping those initial installation gaps in place matters a lot if we want to avoid problems like warping or buckling down the road. Thermal expansion isn't something to ignore when talking about how long these roofing materials will last. Most installers schedule routine checks every few months just to catch any issues before they become major headaches. During these inspections, technicians look closely at joints, seals, and overall sheet alignment while also checking for signs of heat stress. With proper care, polycarbonate roofs maintain their strength and clarity year after year without losing structural integrity.

Preventing Water Pooling and Leaks

Regular checks of polycarbonate roofing for spots where water tends to collect becomes really important, especially following those big rainstorms we sometimes get. Getting good drainage sorted out right from the start when installing these roofs can cut down on leak problems quite a bit. The slope of the roof panels matters too - making sure they're angled properly helps water run off instead of sitting around and causing trouble. Taking care of these things upfront makes all the difference in keeping polycarbonate roofs working well for years without having to deal with constant repairs or replacements because of water damage.