Understanding Multiwall Polycarbonate Sheet Insect-Proofing

How Multiwall Design Blocks Insect Entry

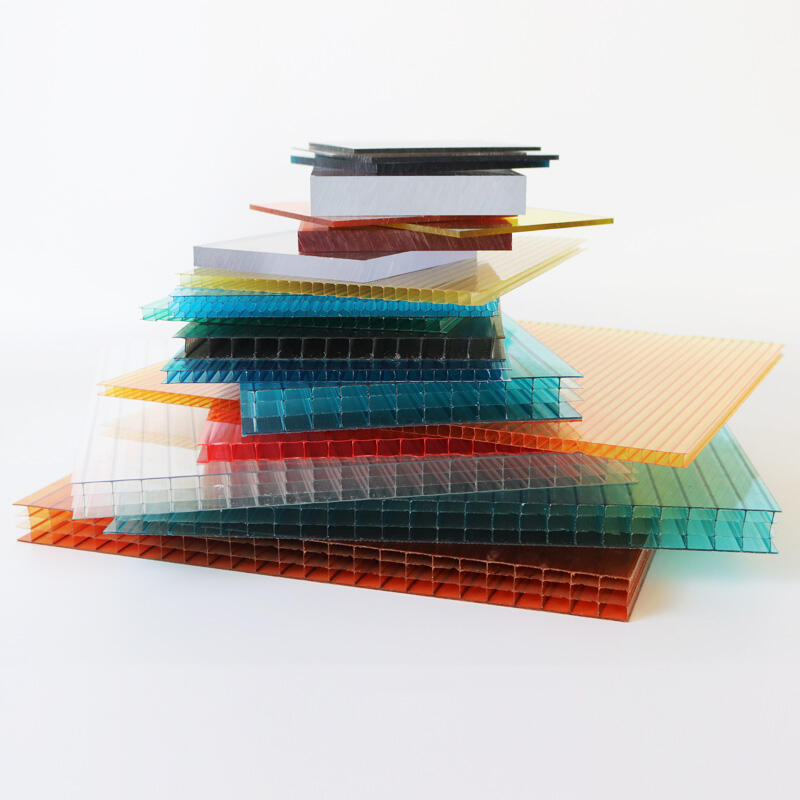

Multiwall polycarbonate sheets give growers a real edge when keeping pests out of their greenhouses. The way these sheets are built with multiple layers makes them tough for bugs to get through. There are actually tiny air pockets sandwiched between each layer, creating all sorts of obstacles for any insect trying to find its way inside. We've seen this work especially well against pesky little critters like aphids and whiteflies who just can't figure out how to maneuver through those complicated spaces. For anyone dealing with serious pest problems in controlled environments, switching to these polycarbonate panels means getting solid protection without needing chemical treatments. Many commercial growers have made the switch simply because they want something reliable that works year after year without constant maintenance headaches.

The Role of Vented Aluminum Tape in Pest Prevention

Vented aluminum tape really helps improve how well multiwall polycarbonate setups keep insects out. When installed properly around those tricky edges and corners, the tape blocks off spots where bugs might otherwise get inside, but still lets air flow through as needed. What makes this stuff so good is that it does two things at once. First, it keeps air moving which stops dampness from building up and causing mold problems. At the same time, it maintains that solid barrier against unwanted visitors. Studies have shown these tapes work pretty well too, cutting down on bug infestations by roughly 80 percent in many cases. For anyone working with polycarbonate panels, getting hold of some quality vented aluminum tape should be part of their standard installation kit if they want to avoid dealing with pest issues later on.

Key Insect-Proofing Features of Polycarbonate Roof Panels

Multi-Layer Structure and Air Gap Sealing

Polycarbonate roof panels are built with multiple layers that boost insulation performance and block out bugs at the same time. Bugs find it really tough to get through these panels, so buildings stay free from pests. What makes this work? There are tiny air spaces between the layers. These air pockets do double duty they keep heat from escaping in winter and stop critters from finding their way inside. The result is better temperature control plus protection against unwanted guests, all while keeping indoor areas intact and undisturbed.

UV-Resistant Coatings to Deter Debris Accumulation

Applying UV resistant coatings to polycarbonate roof panels helps stop them from breaking down and fading under sunlight exposure while also making them last longer and keeping bugs away. The coatings work against buildup of stuff like leaves and pollen that tend to stick around on roofs. This kind of buildup actually draws in insects looking for food sources. So when we apply these special coatings, we see fewer pests hanging around the area. Plus, the panels stay cleaner looking for much longer periods. For building owners concerned about maintenance costs, this means less frequent cleaning and replacement expenses down the road. A well maintained roof panel system just makes sense economically as well as aesthetically speaking.

Tight Seal Compatibility with Frames and Profiles

Getting those polycarbonate panels to fit tightly against different frame types matters a lot when trying to keep insects out. When there's a good snug fit, it basically eliminates the tiny spaces where bugs could sneak in. Many installers have found that special sealing methods work wonders here. Some people swear by silicone sealant while others prefer custom made rubber gaskets depending on what kind of installation they're dealing with. These approaches really do make a difference in keeping pests away from buildings. Most property owners report fewer problems with insects after proper sealing has been done, though complete elimination remains tricky in certain situations.

Benefits of Insect-Resistant Polycarbonate Greenhouse Panels

Hygienic Environment for Plants and Livestock

Insect resistant polycarbonate greenhouse panels create cleaner spaces for growing plants and raising livestock, which is one of their main advantages. These green solutions keep pests out, so there's less chance of disease spreading through crops or affecting animals. Without those pesky insects getting in, farmers can better protect what they grow and raise on their land. Research shows farms using these panels tend to see healthier plants and animals overall. The reason? Simply put, fewer bugs means fewer opportunities for diseases to spread around the property. Most growers who've made the switch notice this difference pretty quickly after installation.

Reduced Maintenance from Pest-Related Damage

Insect resistant panels cut down on the need for ongoing pest control, which saves money on maintenance over time. Greenhouses and barns that switch to polycarbonate panels often see their maintenance bills drop around 30% compared to older buildings made with standard materials. These panels really hold up against bugs and critters, so there's less fixing needed after infestations and fewer calls to exterminators. Farmers and facility managers notice two main benefits: the panels last longer than regular ones, and they work better at keeping pests out. For anyone running an agricultural operation, this kind of panel makes sense both financially and practically in the long run.

Enhanced Thermal Efficiency Through Uncompromised Seals

Polycarbonate panels really boost thermal efficiency because they create tight seals that keep greenhouses at just the right temperature. Studies from agricultural researchers show that good sealing can actually cut energy costs by around 25%. For farmers, this means greener operations without breaking the bank. The savings add up over time, helping both the bottom line and the environment. What's interesting is how these panels maintain consistent temperatures inside even when outside weather fluctuates wildly. They let in light but stop heat loss, making them practical solutions for growers who want to reduce their carbon footprint while still running profitable businesses.

Applications Leveraging Corrugated Polycarbonate Sheet Protection

Residential Patio Covers and Sunrooms

Corrugated polycarbonate sheets work really well for home projects like patios and sunrooms because they can handle so many different situations. Homeowners love how light they are compared to other materials but still hold up against the elements when installed properly. What stands out is that these sheets let daylight come through without getting faded over time from sunlight exposure. People who've used them often mention spending more time outside since their space looks better and feels protected from bugs and critters trying to get inside through gaps between panels. Beyond just looking good, this stuff actually lets folks enjoy their backyard even when it rains or gets chilly at night, something traditional materials just cant match.

Commercial Greenhouse Ventilation Systems

Commercial greenhouses rely heavily on corrugated polycarbonate sheets to improve air circulation while still keeping pests at bay. The way these panels work allows just enough airflow through the structure which is really important for plants to grow properly and cuts down chances of bugs getting in. Growers who have switched to these materials report seeing fewer pest problems overall. Their plants tend to stay healthier too, which means bigger harvests at the end of the season. When growers opt for corrugated polycarbonate instead of other options, they create an environment inside their greenhouse where temperature stays stable and humidity levels don't swing wildly from day to night. Most experienced horticulturists would agree this kind of controlled atmosphere makes all the difference for successful cultivation.

Agricultural Storage Facilities

Farms and storage warehouses rely heavily on corrugated polycarbonate sheets because they protect stored crops from bugs and critters without blocking airflow. The material stands up pretty well against insect infestations and rodent damage, which means farmers lose less of their harvest over time. Many growers have noticed they don't need to spray so much pesticide anymore since switching to these sheets, cutting costs and reducing environmental impact at the same time. Plus, the way these panels let in natural daylight while still shielding against harmful UV rays helps keep fruits and vegetables in better condition during storage. Most farmers report longer shelf life for their products when using this type of covering compared to traditional options.

Installation Best Practices for Maximum Insect Resistance

Proper Flute Orientation and Edge Sealing

Getting the flutes oriented right when installing polycarbonate sheets really matters if we want them to hold up structurally and keep pests out. When installed properly, the sheets actually function as they should, acting as good barriers instead of letting bugs slip through gaps. Most professionals suggest adding some sort of edge seal to make things last longer and create tighter seals around the edges. This makes a big difference in keeping insects at bay. People who take the time to do these steps usually find that their installations resist insect intrusion much better and tend to stay effective for years rather than months.

Choosing Between Polycarbonate vs Aluminum Profiles

Picking the right profile material makes all the difference when it comes to keeping pests out of installations. Polycarbonate profiles stand out because they not only keep heat loss to a minimum but also resist insects much better than aluminum alternatives. The fact that these materials are light weight and can create tight seals means they work really well in situations where stopping bugs from getting inside matters most. Most industry experts recommend going with polycarbonate profiles since they've shown good results over time. These materials just tend to last longer and offer better protection against unwanted critters creeping into vulnerable areas.

Long-Term Maintenance for Sustained Protection

To keep insects away for good, folks need to do some regular upkeep work around here. Cleaning those hard to reach areas between panels and checking all the seals makes a big difference. When these maintenance tasks get done consistently, polycarbonate structures stay strong against bugs much longer than if neglected completely. According to what we've seen in our industry experience, proper care often adds 3-5 extra years onto how long these protective systems last before needing replacement. That means better value for money spent initially on installation costs. The whole point is staying ahead of problems before they start causing headaches later on down the road. Regular inspections catch small issues early while avoiding bigger messes that could damage not just the physical structures but also whatever equipment or products are housed inside them.

Table of Contents

- Understanding Multiwall Polycarbonate Sheet Insect-Proofing

- Key Insect-Proofing Features of Polycarbonate Roof Panels

- Benefits of Insect-Resistant Polycarbonate Greenhouse Panels

- Applications Leveraging Corrugated Polycarbonate Sheet Protection

- Installation Best Practices for Maximum Insect Resistance