Understanding Polycarbonate Sheet Composition and Core Properties

What Is a Polycarbonate Sheet Made Of?

Polycarbonate sheets are thermoplastic polymers containing carbonate groups, formed through an extrusion process that shapes molten resin into durable, optically clear sheets. This composition delivers exceptional impact resistance—up to 250 times stronger than glass—while weighing approximately 50% less, significantly improving handling and installation efficiency in construction and industrial settings.

Key Mechanical and Thermal Properties of Polycarbonate Sheet

Polycarbonate sheets perform reliably across extreme conditions due to their balanced mechanical and thermal characteristics:

- Impact resistance: Withstands 900 J/m² (Charpy impact strength, ASTM D6110)

- Thermal stability: Functions effectively from -40°C to 120°C without deformation

-

Flame retardancy: Meets UL94 V-0/V-2 fire safety ratings

The material also offers an 85% light transmission rate, surpassing most acrylics while resisting UV-induced hazing, as confirmed by the Polymer Engineering Consortium (2024).

Transparency, UV Resistance, and Durability in Polycarbonate Sheet Applications

A co-extruded UV-resistant layer blocks 99.9% of harmful ultraviolet radiation, extending outdoor service life to 10–15 years in applications like skylights and greenhouse panels. Unlike glass, polycarbonate retains 92% of its clarity after a decade of sun exposure, reducing maintenance and replacement needs in architectural installations.

How Polycarbonate Sheet Compares to Glass and Acrylic in Performance

In controlled performance tests, polycarbonate sheets outperform both glass and acrylic across critical metrics:

| Property | Polycarbonate | Glass | Acrylic |

|---|---|---|---|

| Impact Resistance | 250x higher | Baseline | 18x |

| Thermal Expansion | 0.065 mm/m°C | 0.005 | 0.09 |

| Weight (6mm sheet) | 1.2 kg/m² | 15 kg/m² | 7.2 kg/m² |

| This combination of strength, low thermal expansion, and lightweight design makes polycarbonate ideal for security glazing, noise barriers, and hurricane-resistant roofing. |

Solid Polycarbonate Sheet: High Impact Resistance and Optical Clarity

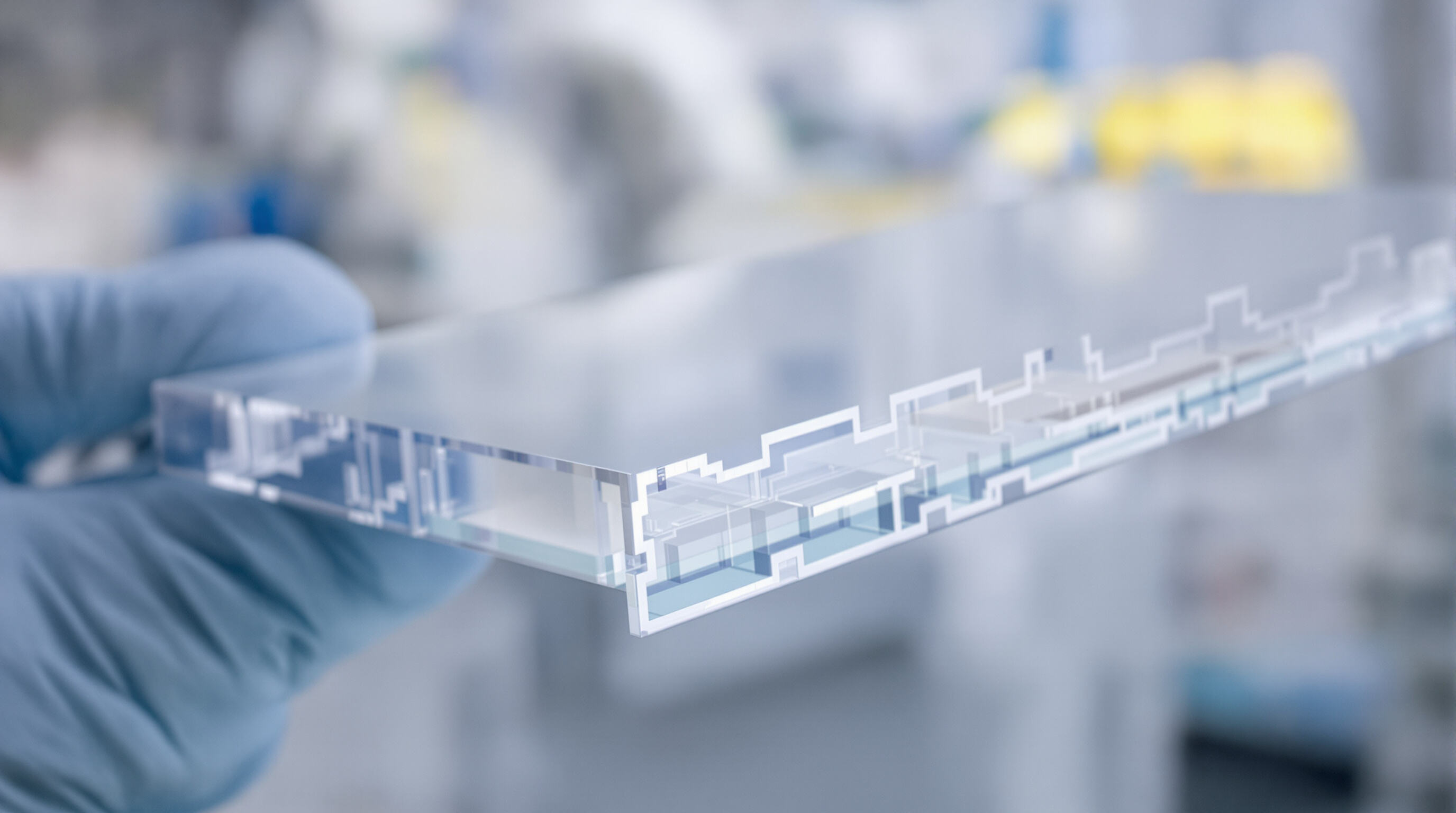

Structure and Manufacturing Process of Solid Polycarbonate Sheet

Solid polycarbonate sheets are manufactured via extrusion or injection molding, producing a monolithic, air-gap-free structure. Available in thicknesses from 2mm to 12mm, they maintain uniform density and glass-like clarity. Advanced co-extrusion integrates UV-protective layers during production, eliminating the need for post-treatment and ensuring long-term optical performance.

Impact Resistance and Safety Standards for Solid Polycarbonate Sheet

Solid polycarbonate offers impact resistance that's around 200 times better than regular glass according to ANSI Z87.1-2024 standards. The material can actually handle forces over 900 psi before showing any cracks. When it comes to safety requirements, this stuff checks all the boxes. It satisfies the strict UL 752 Level 1 ballistic protection needed for those bullet resistant installations many facilities require these days. Tests done by Underwriters Laboratories back in 2023 showed something pretty impressive too. After sitting out in direct sunlight for fifteen whole years straight, the polycarbonate maintained its structural strength because manufacturers added special light stabilizers during production.

Architectural and Security Applications of Solid Polycarbonate Sheet

Offering vandal resistance and 90% light transmission, solid polycarbonate is widely used in high-demand environments:

- Stadium roofing compliant with hail impact standards (ASTM D7192)

- Bank teller windows meeting forced-entry resistance (EN 356 Class P8A)

- Museum skylights that protect artifacts with UV filtering

At half the weight of laminated glass, these sheets reduce structural load and support costs, backed by 10–25 year warranties in outdoor use.

Multiwall and Corrugated Polycarbonate Sheets: Lightweight Solutions for Insulation and Weather Resistance

Thermal Efficiency and Structural Design of Multiwall Polycarbonate Sheet

Multiwall polycarbonate sheets utilize internal air chambers to minimize heat transfer, improving thermal insulation by up to 50% compared to single-layer alternatives. This design reduces HVAC energy consumption by 15–30%, making it a preferred choice for skylights, greenhouses, and sound barriers where temperature control is essential.

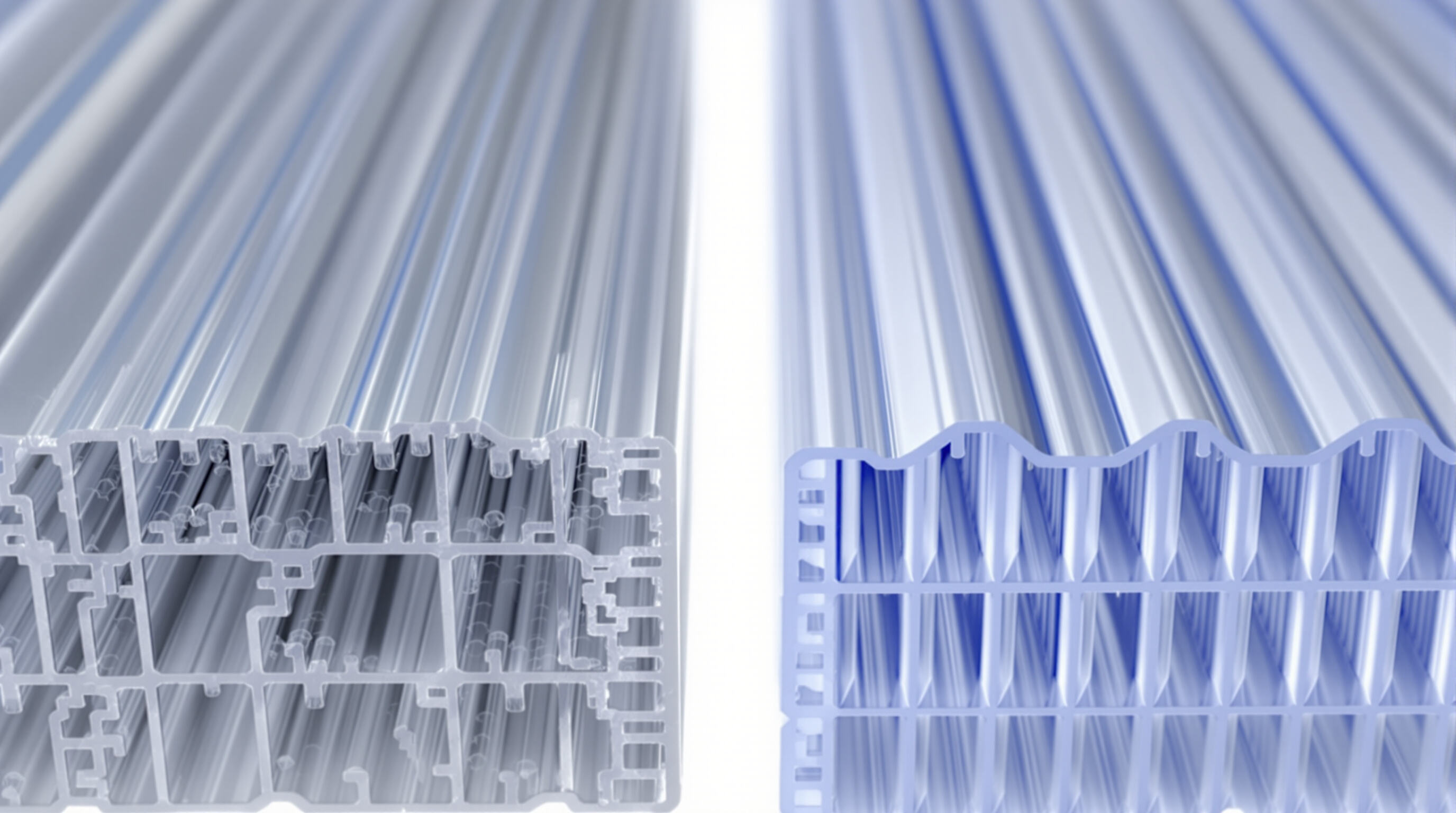

Twin-Wall, Triple-Wall, and Multi-Layer Configurations for Building Applications

Layer configuration determines performance and application suitability:

- Twin-wall: Offers optimal cost-to-insulation ratio for residential roofing

- Triple-wall: Increases rigidity for industrial canopies and commercial structures

-

5+ layers: Delivers maximum thermal retention in cold climates

Despite their insulating structure, these sheets weigh 50% less than glass and support loads up to 1.5 kN/m².

Corrugated Polycarbonate Sheet: Advantages in Roofing and Extreme Climates

The corrugated profile enhances structural strength, enabling resistance to hail impacts up to 25 mm in diameter (ASTM D5420). Its lightweight nature allows 30% faster installation than metal roofing, with a service life of 15–25 years even in high-UV environments.

UV Protection and Service Life in Outdoor Installations

A co-extruded UV-blocking layer prevents degradation by filtering 99% of UV radiation while maintaining 88% light transmission. Per ISO 4892 accelerated weathering tests, these sheets exhibit less than 5% change in yellowness index after 10,000 hours—twice the durability of uncoated variants.

Specialty and Aesthetic Polycarbonate Sheet Variants for Custom Applications

Foamed Polycarbonate Sheet: Lightweight and Cost-Effective Alternative

When foamed polycarbonate goes through the extrusion process, it develops these tiny air pockets throughout the material, which cuts down on overall weight by around 20 to 35 percent while still keeping most of its structural integrity intact. Because it's so much lighter than regular versions, this type works great for things that don't need full structural support like trade show booths, office dividers, or sound absorbing panels. The lighter weight makes a real difference when shipping large quantities too. Companies report saving about 18% on transportation expenses when switching from standard sheets to this foam version, which explains why many manufacturers are turning to it for big-scale production runs where every penny counts.

Textured, Colored, and Patterned Polycarbonate Sheets for Design Flexibility

When it comes to design, manufacturers often turn to embossed textures, gradient color shifts, and those eye-catching prismatic effects to satisfy both looks and function requirements. Frosted glass finishes work great for creating soft, even lighting on privacy screens where people don't want harsh reflections. Meanwhile, those fancy prismatic surfaces actually help redirect sunlight in greenhouses and other farming environments. There's this thing called co-extrusion that keeps UV protection built right into the material without messing up how everything looks together. Pretty important stuff when talking about outdoor sculptures or those big brand displays we see everywhere nowadays. Most designers seem pretty fond of these customizable panels too. Industry surveys suggest somewhere around 8 out of 10 professionals choose them whenever they need something that lasts but still looks good over time.

How to Choose the Right Polycarbonate Sheet Based on Application Needs

Comparative Overview: Strength, Light Transmission, and Insulation by Type

Different polycarbonate sheet types serve distinct performance needs:

- Solid sheets: Deliver maximum impact resistance (up to 250x stronger than glass) and 89% light transmission, ideal for security glazing and transparent roofing

- Multiwall sheets: Provide high thermal insulation—50% more efficient than single-pane glass—and transmit 82% of light, suited for skylights and energy-efficient enclosures

- Corrugated sheets: Combine moderate-to-high insulation with weather resilience and weigh an average of 1.2 kg/m², making them optimal for agricultural and industrial roofing

| Property | Solid Sheet | Multiwall Sheet | Corrugated Sheet |

|---|---|---|---|

| Light Transmission | 89% | 82% | 78% |

| Impact Resistance | 900 kJ/m² | 650 kJ/m² | 550 kJ/m² |

| Thermal Insulation | Moderate | High | Moderate-High |

Balancing Cost and Performance Across Polycarbonate Sheet Variants

Thicker panels (4–10mm) offer 35% greater durability in outdoor use but come at a 20–40% premium over 2mm sheets. UV-protected variants extend service life by 8–12 years, cutting long-term replacement costs by up to 60% over a 15-year period.

Matching Polycarbonate Sheet Types to Industry Requirements

- Construction: Uses multiwall sheets for skylights (70–85% light transmission) and noise reduction (25 dB attenuation)

- Agriculture: Relies on 6mm–16mm corrugated sheets for optimal light diffusion and hail resistance in greenhouses

- Security: Requires solid sheets of 12mm–20mm thickness that meet ISO 16933 ballistic standards

- Automotive: Employs 1.5–3mm tinted polycarbonate to achieve 40% weight savings over tempered glass, enhancing fuel efficiency and design flexibility (2024 Polymer Engineering Study)

FAQ

What are polycarbonate sheets made of?

Polycarbonate sheets are made of thermoplastic polymers with carbonate groups, resulting in impact-resistant and lightweight sheets formed through an extrusion process.

How does polycarbonate compare to glass and acrylic?

Polycarbonate outperforms glass and acrylic in critical areas like impact resistance, weight, and thermal expansion, making it ideal for a variety of applications.

What are the benefits of using solid polycarbonate sheets?

Solid polycarbonate sheets offer high impact resistance, optical clarity, and meet various safety standards, making them suitable for architectural and security purposes.

How do multiwall polycarbonate sheets improve thermal insulation?

Multiwall sheets have internal air chambers that reduce heat transfer, enhancing thermal insulation and reducing energy consumption in applications like skylights and greenhouses.

What applications are best suited for corrugated polycarbonate sheets?

Corrugated sheets are ideal for roofing and extreme climates due to their structural strength, quick installation, and long service life.

Table of Contents

- Understanding Polycarbonate Sheet Composition and Core Properties

- Solid Polycarbonate Sheet: High Impact Resistance and Optical Clarity

- Multiwall and Corrugated Polycarbonate Sheets: Lightweight Solutions for Insulation and Weather Resistance

- Specialty and Aesthetic Polycarbonate Sheet Variants for Custom Applications

- How to Choose the Right Polycarbonate Sheet Based on Application Needs

- FAQ