Thermal Resistance and Operating Temperature Range of Polycarbonate Sheets

Heat Deflection Temperature (HDT) and Its Role in Polycarbonate Stability

Polycarbonate sheets typically have a heat deflection temperature (HDT) somewhere around 137 to 140 degrees Celsius when tested according to standard methods (Inplex LLC 2023). Basically, this number tells us how hot things can get before the material starts bending or warping under pressure. For structures such as greenhouse covers or factory roofs that need to hold up in warm environments, knowing this HDT becomes really important. Compared to regular tempered glass, polycarbonate handles sudden changes in temperature much better. It doesn't crack or break unexpectedly even when exposed to quick heating cycles, which makes it a safer choice for many building applications.

Long-Term Use Temperature Limits of Polycarbonate (-40°C to 135°C)

Polycarbonate sheets work pretty well across temperatures ranging from minus 40 degrees Celsius all the way up to 135 degrees Celsius. Research shows they maintain around 85 percent of their tensile strength even when cold as -40°C according to a report published by UNQPC back in 2023. The strength starts dropping off gradually once things get hotter than 100°C though. Most manufacturers will tell us that brief contact with 135°C isn't going to hurt much but keeping them there consistently past 130°C speeds up the aging process significantly. Because these materials can handle such extreme conditions, we see them used everywhere from building projects in freezing climates right down to parts inside cars where temperature fluctuations happen constantly, and no special treatment is needed for the material itself.

Effect of High and Low Temperatures on Mechanical Strength

- High temperatures (>100°C): Reduce flexural modulus by 18–22% and increase ductility

-

Low temperatures (-40°C): Boost impact resistance by 30% while maintaining dimensional stability

These behaviors stem from polycarbonate’s unique molecular structure, which delays brittle transitions until below -100°C.

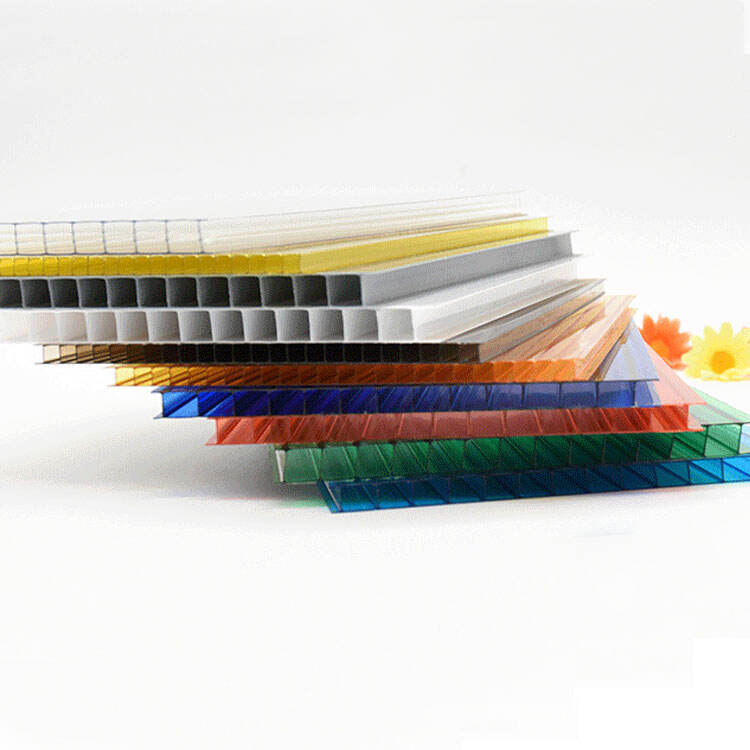

Thickness-Dependent Thermal Performance of Polycarbonate Sheets

Thicker panels (≥6mm) offer 15–20% higher heat resistance due to increased mass and lower thermal conductivity (0.19 W/m·K). Multiwall sheets leverage air gaps between layers to improve insulation efficiency by 40% compared to solid panels, making them ideal for extreme environments.

Mechanical Property Changes in Polycarbonate Sheets Under Thermal Stress

Impact of Heat and Cold on Polycarbonate Flexibility and Rigidity

When materials face extreme temperatures, their mechanical characteristics change quite dramatically. For instance, at around 135 degrees Celsius, something called elongation at break drops about 70% from what we see at normal room temps, which basically means the material becomes much less flexible according to research published by Song and colleagues back in 2023. On the flip side, when things get really cold down near minus 20 degrees Celsius, these same materials actually become stiffer by roughly 30%, yet still hold together pretty well structurally. This was observed in various tests on thermoplastic polymers as reported by Hafad's team in 2021. The fact that these properties bounce back and forth within such a wide temperature window from minus 40 all the way up to 135 degrees shows just how versatile polycarbonate can be for different applications.

Thermal Aging Effect on Mechanical Behavior of Polycarbonate

Prolonged thermal exposure causes permanent molecular changes in polycarbonate. Research shows a 25% reduction in impact resistance after five years at 90°C. This degradation stems from chain scission and reduced free volume, particularly in load-bearing scenarios. To counteract this, manufacturers use UV-stabilized additives and crosslinking techniques to extend service life.

Enthalpy Relaxation and Its Correlation with Mechanical Response

Enthalpy relaxation explains time-dependent stiffness increases under thermal stress. As polymer chains slowly approach equilibrium below the glass transition temperature (~147°C), Young's modulus rises by 15–20% over six months. This structural evolution affects long-term dimensional stability and necessitates consideration of creep resistance in engineering designs.

Ductile-Brittle Transition in Polycarbonate at Low Temperatures

When temperatures drop below -30 degrees Celsius, polycarbonate goes through a significant change where it becomes much more sensitive to notches, around four times more so than at normal temps. Even though it still holds up pretty well against impacts, with tests showing about 60 joules per square meter at -40°C, which is actually way better than glass can handle, how we design the joints really matters if we want to prevent those stress points from failing. That's why in places where it gets super cold, installers usually go for thicker panels, often 12mm or more, and pair them with these flexible edge connectors that let the material move without cracking. We've seen this work particularly well in northern regions where winter conditions are extreme.

Physical Aging, Dimensional Stability, and Thermal Expansion

Phenomenon of Physical Aging in Polycarbonate Over Time

When polycarbonate ages physically, it goes through a slow process where its internal structure rearranges itself over time. This aging shows up as changes in what scientists call relaxation enthalpy (ΔHr) and something known as fictive temperature (Tf). Research using calorimetry has shown that these amorphous areas inside the material shift towards equilibrium, and this depends heavily on how the material was heated before (as reported in Nature 2023). Even though most polycarbonate keeps about 85 percent of its original strength after sitting around for ten years at room temperature (around 23 degrees Celsius), things change when exposed to higher temps. Warmer conditions speed up the aging process because molecules move around more freely and there's less overall order in the system, which leads to faster degradation.

Structural Relaxation and Dimensional Stability Under Thermal Cycling

Going back and forth between -40 degrees Celsius and 100 degrees causes materials to relax structurally over time, which cuts down on free space inside them by about 2.3 percent when tested under speeded-up conditions. To combat this issue, companies typically apply special UV resistant coatings and incorporate designs that fight against stress buildup. Looking at actual test results, we find that sheets measuring 6 millimeters thick only showed around 0.08 millimeters per meter of size change after being subjected to daily temperature swings for half a year. These findings basically tell us these materials work well enough even in places where temperatures can jump around plus or minus 50 degrees Celsius regularly.

Temperature Extremes and Thermal Expansion of Polycarbonate Panels

Polycarbonate has a thermal expansion coefficient ranging between about 65 to 70 times 10 to the minus sixth power per degree Celsius, which means it needs careful spacing during installation in areas where temperatures fluctuate widely. When temps fall below minus 40 degrees, these panels actually shrink around 0.3% for every 10 degree drop. At the other end of the spectrum, they can stretch out by roughly 1.2% when heated to 135 degrees Celsius. From what we've seen in actual installations, good quality thermal joints generally maintain dimensional stability within plus or minus 1.5 millimeters per meter over the course of a year. Interestingly enough, multiwall sheets tend to expand about 18 percent less than their solid counterparts because those little air pockets inside help take some of the pressure off when temperatures change.

Environmental Durability and Safety Performance Under Thermal Conditions

Temperature Effects on Polycarbonate Weathering and UV Resistance

Polycarbonate retains 90% UV resistance after a decade in moderate climates, but thermal stress degrades performance. Exposure above 120°C reduces UV stability by 15–20% within two years (Materials Performance Report 2023). However, standard grades maintain ≥85% light transmission through 1,000-hour thermal cycling tests (-40°C to 125°C) without yellowing.

Coated Polycarbonate Degradation Under Thermal Conditions

Dual-layer coated variants offer enhanced resilience, retaining 94% weatherability after 5,000 hours at 85°C and 85% relative humidity (Advanced Polymer Studies 2024). Key benchmarks include:

| Test Parameter | Threshold Value | Performance Standard |

|---|---|---|

| Continuous Service Temperature | -50°C to 145°C (-58°F to 293°F) | ASTM D638 |

| Thermal Shock Resistance | 500 cycles (-40°C – 120°C) | ISO 22088-3 |

Fire Resistance of Polycarbonate Sheets at Elevated Temperatures

Polycarbonate achieves UL 94 V-0 ratings, self-extinguishing within 15 seconds. At 450°C (842°F), it chars without dripping and maintains structural integrity for 30–90 minutes depending on thickness (Fire Safety Journal 2023). Compared to glass, it emits 80% fewer toxic fumes, enhancing safety during evacuation.

Best Practices for Climate-Specific Selection of Polycarbonate Sheets

Matching Polycarbonate Sheet Properties to Regional Temperature Profiles

Select polycarbonate sheets engineered for regional extremes. Grades rated for -40°C to 135°C (Polycarbonate Council 2024) perform reliably across 98% of global climates. In tropical zones, choose UV-resistant grades with 2.5–3.2 mm thickness to minimize warping. For arctic conditions, impact-modified formulations prevent brittleness while preserving 92% of room-temperature flexibility.

Design Considerations for Thermal Movement in Polycarbonate Installations

When working with polycarbonate materials, it's important to remember that they expand at around 0.065 mm per meter per degree Celsius temperature change. A good rule of thumb is to leave about 32.5 mm space between joints on a 10 meter panel when dealing with annual temperature swings of roughly 50 degrees. Desert environments present special challenges because temperatures can jump between 25 to 40 degrees during normal day/night cycles. That's why many installers prefer using compression fit fasteners over traditional rigid clamps in these areas. According to recent industry reports, following these guidelines cuts down on weather related problems by nearly three quarters compared to regular installation methods, though actual results may vary depending on local conditions and material quality.

By aligning sheet specifications with climate demands and integrating flexible mounting solutions, designers ensure optimal thermal performance across polycarbonate applications.

FAQ Section

What is the heat deflection temperature of polycarbonate sheets?

Polycarbonate sheets have a heat deflection temperature (HDT) around 137 to 140 degrees Celsius, indicating the temperature at which the material begins to warp under pressure.

Can polycarbonate sheets withstand extreme temperatures?

Yes, polycarbonate sheets can handle temperatures ranging from -40°C to 135°C, making them suitable for diverse environments including freezing climates and inside cars where temperature fluctuation is frequent.

How does temperature affect the mechanical strength of polycarbonate?

High temperatures reduce flexural modulus and increase ductility, whereas low temperatures boost impact resistance while maintaining dimensional stability.

Do thicker polycarbonate panels offer better thermal performance?

Yes, thicker panels provide higher heat resistance due to increased mass and lower thermal conductivity. Multiwall sheets enhance insulation efficiency by leveraging air gaps between layers.

How does aging affect polycarbonate's mechanical behavior?

Prolonged thermal exposure causes permanent molecular changes, reducing impact resistance. Manufacturers use UV-stabilized additives and crosslinking techniques to extend service life.

Table of Contents

- Thermal Resistance and Operating Temperature Range of Polycarbonate Sheets

- Mechanical Property Changes in Polycarbonate Sheets Under Thermal Stress

- Physical Aging, Dimensional Stability, and Thermal Expansion

- Environmental Durability and Safety Performance Under Thermal Conditions

- Best Practices for Climate-Specific Selection of Polycarbonate Sheets

-

FAQ Section

- What is the heat deflection temperature of polycarbonate sheets?

- Can polycarbonate sheets withstand extreme temperatures?

- How does temperature affect the mechanical strength of polycarbonate?

- Do thicker polycarbonate panels offer better thermal performance?

- How does aging affect polycarbonate's mechanical behavior?