Design Flexibility: Color, Texture, and Light Control with Colored Polycarbonate Sheets

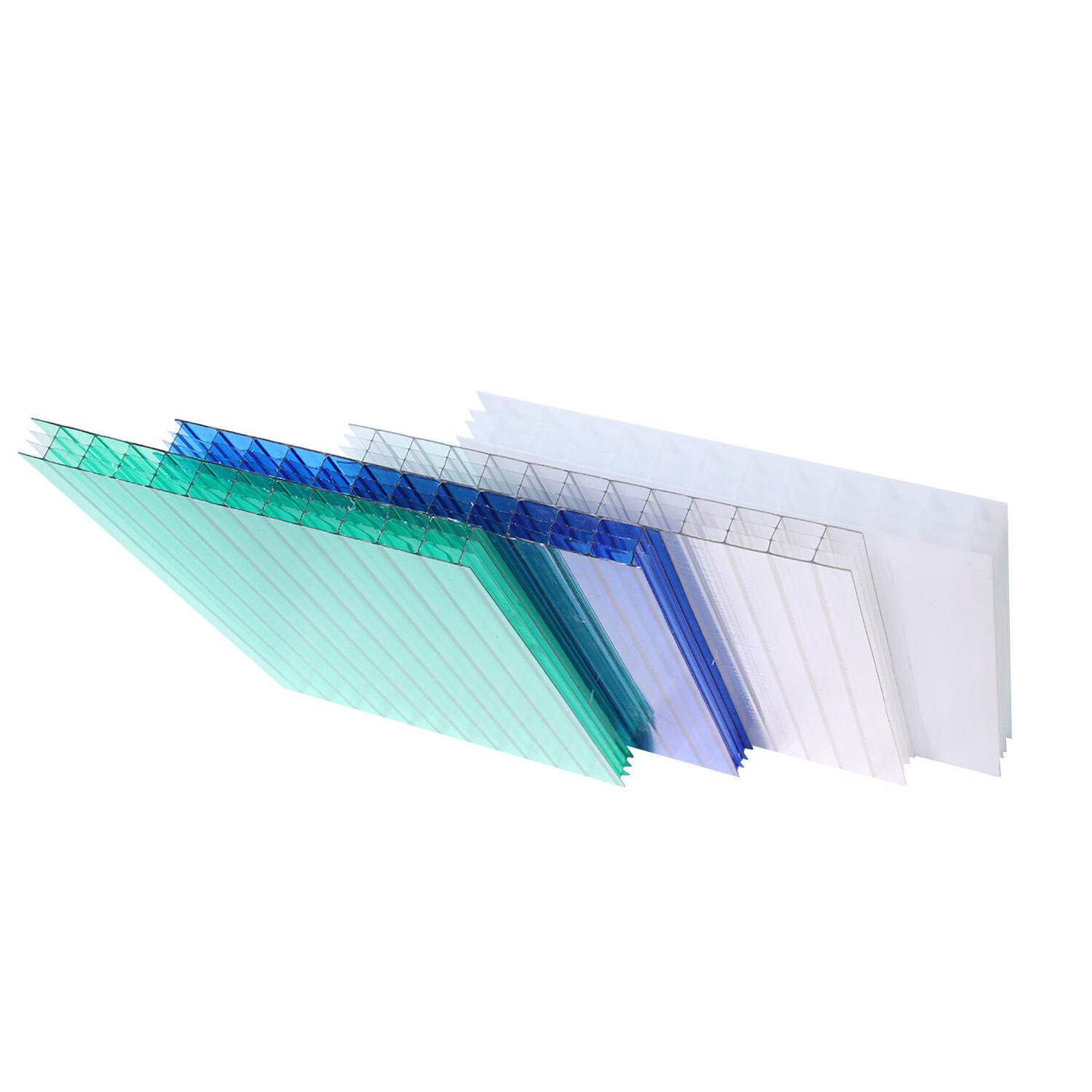

Colored polycarbonate sheets offer exceptional design versatility by combining aesthetic customization with functional performance. Architects use these sheets to create visually striking spaces that align with brand identities or thematic concepts, leveraging full-spectrum color options and advanced light control technologies—all without compromising material durability.

Custom color options and spectrum compatibility for brand-aligned design

Modern manufacturing techniques make it possible to match Pantone colors with incredible accuracy, which means companies can really embed their brand identity into building materials and design features. When it comes to how much light passes through these colored materials, we're talking about anywhere between half to almost three quarters of available light getting through, based on how dark or light the tint is. The result? Colors stay vibrant even when exposed to sunlight throughout the day, so businesses save money on extra lighting costs. Retail stores that have started using deep cobalt blue panels in their interior spaces have seen customers spend around 30 percent more time inside those shops, some studies in environmental psychology suggest. The combination of right colors and proper lighting just makes spaces feel bigger and more inviting.

Surface texturing, tinting, and backlighting techniques for dynamic visual effects

Designers enhance visual impact through three key techniques:

- Laser-etched texturing: Introduces decorative privacy patterns while diffusing light evenly

- Variable-density tinting: Creates smart facades that adapt to solar intensity, darkening under high UV exposure

- Integrated LED backlighting: Delivers energy-efficient glowing surfaces, using 50% less power than neon alternatives

These methods exploit the material’s superior light diffusion. Frosted polycarbonate, for instance, transmits up to 95% of light while eliminating transparency—making it ideal for daylight-permitting partitions without compromised privacy. Together, these capabilities allow architects to shape both space and mood through controlled luminosity.

Performance-Driven Benefits of Tinted Polycarbonate Sheets

UV resistance, weatherability, and long-term clarity retention

Tinted polycarbonate sheets come with special UV blocking layers built right into them during manufacturing. These layers stop the sheets from turning yellow or becoming brittle over time, so they stay clear and strong for years. Even after sitting outside for ten whole years through all sorts of weather conditions like heavy rain, ice storms, and extreme temperatures, these sheets still let through more than 90% of available light. What really stands out is how tough they are too. Tests show that polycarbonate can handle impacts about 250 times better than regular glass would. That means buildings in areas where hurricanes or tornadoes happen regularly can rely on this material without constant worry about damage. Because these sheets last so long without needing repairs or replacements, building owners end up saving money across the entire lifespan of their structures when compared to cheaper alternatives that break down faster.

Controlled light diffusion and solar heat gain reduction for energy efficiency

Polycarbonate sheets with their multi wall design spread sunlight evenly throughout spaces, which cuts down on harsh glare while letting plenty of natural light come through. This means buildings can rely less on electric lights during the day, potentially saving around 30% on lighting costs. The special infrared reflective colors used in these sheets stop nearly all UV rays from getting through and also reduce how much heat builds up inside. As a result, rooms stay cooler by about 5 to 8 degrees Celsius when compared to regular glass windows. When paired with good thermal insulation properties (some have U values as low as 1.0 W per square meter Kelvin), this combination helps cut cooling expenses by roughly 35% each year in warmer regions. These features make polycarbonate sheets a smart choice for anyone looking to build or retrofit structures with better energy efficiency and environmental friendliness.

Architectural Integration: From Façades to Interiors Using Colored Polycarbonate Sheets

Structural and aesthetic roles in modern façades, skylights, and interior partitions

Colorful polycarbonate sheets do more than just look good on buildings—they actually work hard structurally too. When used as exterior cladding, these sheets stand up to harsh weather conditions and impacts, but what really catches attention is how they let architects play with bold colors and tints that define a building's character. The stuff is incredibly tough, about 200 times stronger than regular glass, which explains why we see it so often in areas where people walk through constantly. For skylights, the material spreads natural light evenly throughout a space without causing annoying glare, and it cuts down on unwanted heat from sunlight by around 30% compared to traditional glass options. Inside buildings, translucent colored panels keep spaces bright while still providing needed privacy between sections, cutting down on electricity bills for artificial lighting. Some manufacturers even offer special textured surfaces or versions that can be lit from behind, creating striking effects in places like office reception areas, shopping malls, and government buildings. No wonder this material has become such a go-to choice for designers looking to balance form with function in contemporary construction projects.

Commercial Applications: Signage, Retail, and Creative Installations with Polycarbonate Sheets

Color polycarbonate sheets work really well in commercial settings where things need to last, be seen clearly, and represent a brand effectively. Many retailers install these tinted, see-through panels for signs, displays, and safety barriers because they don't break easily and keep their colors looking good even after years of sun exposure. Museums often bend and shape this material into creative exhibits while combining it with LED lights to make spaces feel more engaging. Trade show organizers love how easy it is to form into custom shapes that stand out from competitors. For bus stations and billboards outside, the tough polycarbonate signs stay clear and readable for about a decade even when rain, snow, or wind hits them hard. The combination of being able to mold almost anything plus standing up against damage means businesses across many industries rely on polycarbonate whenever they need something both attractive and durable for the long haul.

FAQ

- What are colored polycarbonate sheets used for? Colored polycarbonate sheets are used for aesthetic and functional design purposes, including building facades, interior partitions, signage, and creative installations.

- Do colored polycarbonate sheets offer UV protection? Yes, they come with UV-blocking layers to prevent yellowing and brittle degradation over time.

- How do colored polycarbonate sheets affect energy efficiency? They diffuse light evenly, reducing glare and decreasing reliance on electric lighting, while their infrared reflective colors reduce solar heat gain, contributing to lower cooling costs.

- Can colored polycarbonate sheets be customized? Absolutely, modern manufacturing allows for precise matching of Pantone colors to enhance brand identity and design aesthetics.

Table of Contents

- Design Flexibility: Color, Texture, and Light Control with Colored Polycarbonate Sheets

- Performance-Driven Benefits of Tinted Polycarbonate Sheets

- Architectural Integration: From Façades to Interiors Using Colored Polycarbonate Sheets

- Commercial Applications: Signage, Retail, and Creative Installations with Polycarbonate Sheets