Why Polycarbonate Requires Special Cleaning Care

Understanding the sensitivity of polycarbonate surfaces

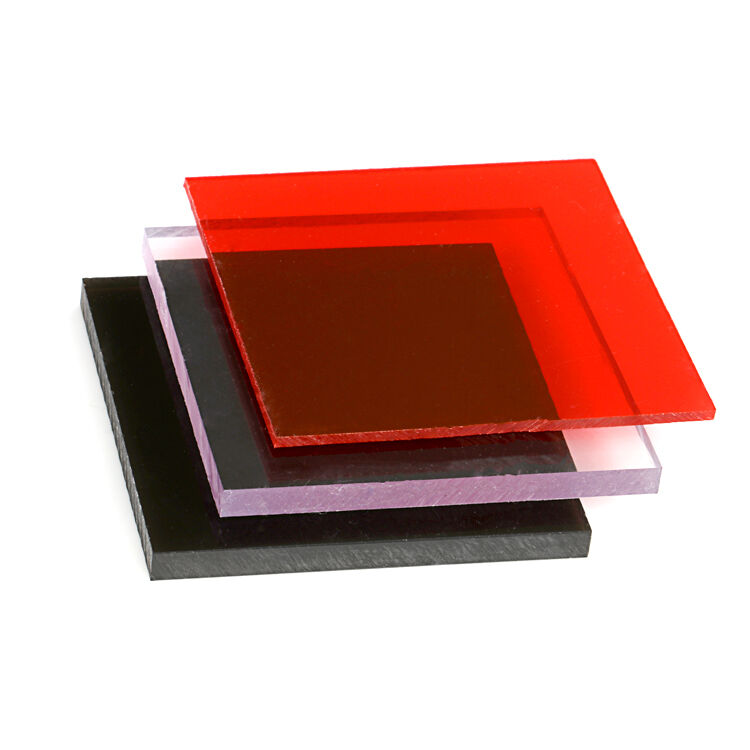

What makes polycarbonate so tough against impacts? Look at its molecular makeup. But there's a tradeoff here. The material's flexibility that gives it such great shock absorption also means the surface isn't as hard as glass. This softness leaves polycarbonate prone to those tiny scratches we barely notice and reacts badly with certain chemicals over time. Now about that UV protection layer applied during manufacturing. It plays a critical role in keeping the material from turning yellow or becoming brittle under sunlight exposure. However, this protective film is pretty fragile stuff. Industry insiders have seen their share of problems where improper cleaning methods cause early failure in polycarbonate products. Around 40 percent of these failures happen because people just don't realize how sensitive the surface actually is to regular cleaning agents and abrasive materials.

Common risks: Scratches, chemical degradation, and UV layer damage

Three interrelated threats accelerate deterioration during cleaning:

- Scratch accumulation: Even fine dust particles act as abrasives when rubbed across the soft surface, creating light-diffusing imperfections that worsen with repeated contact.

- Chemical degradation: Solvents like acetone or alkaline cleaners (e.g., ammonia-based formulas) disrupt polymer chains, initiating stress cracks and reducing impact resistance by up to 40%.

- UV coating erosion: Alkaline cleaners degrade the protective layer, diminishing weather resistance by 60% over time, according to peer-reviewed polymer durability studies.

These effects compound: scratched surfaces attract more dust electrostatically, prompting more frequent—and often harsher—cleaning, which further degrades both clarity and structural performance. Damaged panels typically require replacement 3–5 years earlier than those maintained correctly.

Debunking the myth: 'Cleaner = shinier = better'

Using aggressive polish or those high pH cleaners might make things look better for a while, but they actually cause tiny bits of damage that builds up over time. Studies indicate that when polycarbonate gets scrubbed with strong chemicals, it tends to lose about 30% more UV protection each year compared to panels kept clean with regular neutral solutions. What really matters for keeping surfaces clear and durable isn't just covering up flaws or rubbing them away. The key lies in protecting that original UV layer and reducing wear and tear by going easy on the material with proper care techniques instead of rough handling.

Step-by-Step Safe Cleaning Process for Polycarbonate

Pre-rinse to remove abrasive debris and prevent scratches

Begin by giving the surface a gentle rinse first. A simple garden hose works well, or just fill up a bucket with clean water and get rid of all that loose dust, pollen stuff, and whatever else has settled on there from the environment. Why does this matter so much? Well, polycarbonate actually scratches about twice as easily compared to regular glass. When people drag those tiny abrasive particles across it while cleaning, they end up creating those annoying little micro-scratches that never go away. And please skip the high powered pressure washers above 1,200 PSI. The sheer force can really mess things up by peeling off protective coatings or worse yet, push water right into the edges where panels meet, causing bigger problems down the road.

Using mild detergent, lukewarm water, and soft cloths

To make the cleaning solution, combine one teaspoon of pH neutral dish soap with a gallon of warm water, but keep it below 40 degrees Celsius or around 104 Fahrenheit. Going over that temperature can actually damage surfaces through heat stress, and adding anything too alkaline or acidic will mess with the protective UV coating. When applying, go for lint free microfiber cloths or just slightly wet cellulose sponges. The microfiber stuff works wonders really reducing scratches by about 80 percent when tested against regular cotton towels on polymer surfaces. Most people find they get much better results with these materials anyway.

Proper wiping techniques to avoid streaks and surface stress

When cleaning panels, always go with straight strokes that overlap each other along the longest side of the panel. Avoid going in circles at all costs since those will leave behind annoying swirl marks. Don't press too hard either because too much force can actually crack the surface or create those white stress lines nobody wants to see. Get rid of soap right away once done washing. Leftover soap just sits there drying out and turning everything cloudy looking. With vertical surfaces, start from the top and move downward so water runs off naturally. Most people find this approach works wonders for preventing streaks and those odd distortions that sometimes appear. Industry experts back up this technique as well, though they probably wouldn't put an exact number on how effective it is.

Recommended Cleaning Supplies and Solutions

Best tools: Microfiber cloths, soft sponges, and plastic-safe cleaners

Microfiber cloths work best because they grab dust and dirt without rubbing harshly against surfaces. Cellulose sponges are good too, especially when just damp rather than soaked through, since they provide gentle contact that won't scratch things up. Don't go using paper towels, those hard bristle brushes, or any kind of scouring pad though. The rough fibers in these materials actually leave tiny scratches behind that make surfaces look dull and start turning yellow faster over time. When cleaning plastic items, it's important to match the right tool with a cleaner made specifically for plastics. Regular glass cleaners usually have alkaline ingredients which can slowly eat away at the special UV protection layer found on many polycarbonate products.

Safe DIY and commercial solutions: Mild soap, vinegar mix, and pH-neutral cleaners

The easiest do-it-yourself fix works wonders too: mix about a teaspoon of gentle dish soap into a gallon of warm water. This combination does a great job at removing dirt and grease without relying on harsh chemicals. When dealing with stubborn mineral stains from hard water, try mixing one part white vinegar with three parts regular water. The acid in the vinegar helps break down those deposits without damaging surfaces. Store bought cleaners labeled as pH neutral are also good options for cleaning acrylic and polycarbonate materials. Check the packaging to ensure it's safe for these plastics and falls within the 6 to 8 pH range. Before applying anything new, spot test in an area where nobody will notice if something goes wrong. Stay away from products containing acetone, ammonia, bleach or any alcohol based stuff though. These substances actually eat away at the plastic structure over time and can make materials more prone to cracking under stress.

Cleaning Products and Tools to Avoid

Harmful chemicals: Windex, acetone, ammonia, and solvents

Products containing ammonia such as popular glass cleaners can permanently fog up polycarbonate surfaces because they actually break apart the material's molecular structure. Strong chemicals like acetone and paint thinners strip away the outer layer, whereas really acidic or alkaline solutions eat away at the protective coating that blocks harmful UV rays. Studies on material safety show that using these harsh cleaners cuts down on how well the material resists impacts by around 40%, mainly through tiny cracks forming in the surface. When choosing cleaning products, it's important to check the pH level first. The best results come from formulas that fall within the neutral range between pH 6 and 8, which helps maintain both the strength and clarity of the material over time.

Risks of pressure washing and abrasive scrubbing tools

Pressure washers exceeding 1,200 PSI risk delaminating UV coatings and forcing moisture between multi-layer panels—leading to fogging or edge corrosion. Abrasive tools like steel wool, nylon scrub pads, or even rough sponges generate micro-scratches that:

- Reduce light transmission and clarity

- Trap contaminants, accelerating soiling and yellowing

- Compromise long-term weather resistance

A 2023 polymer durability study found non-abrasive cleaning methods maintained 98% optical clarity after two years, versus just 74% for panels cleaned with abrasive pads—underscoring why gentleness isn’t optional—it’s foundational to performance.

FAQs on Cleaning Polycarbonate

Why is polycarbonate sensitive to scratches?

Polycarbonate is a flexible material, making it great for impact resistance but prone to scratches as its surface is softer than glass.

What cleaning agents should be avoided on polycarbonate?

Avoid using ammonia-based cleaners, acetone, bleach, and other harsh solvents as they can damage the protective UV layer and the material itself.

Are there any DIY cleaning solutions for polycarbonate?

Yes, a mild solution of dish soap and warm water is effective for regular cleaning. For hard water stains, a mix of one part white vinegar with three parts of water is recommended.

Why is pre-rinsing important before cleaning polycarbonate?

Pre-rinsing removes loose dust and debris that might scratch the surface when wiped, helping to prevent micro-scratches.