From Passive Glazing to Active Building Skins: The Evolution of Polycarbonate Panels

Historical Development of Polycarbonate Panel Applications in Architecture

Polycarbonate panels first became popular back in the 70s when people started using them mainly as covers for greenhouses. They were really good at resisting impacts and letting through about 90% of available light. When architects began experimenting with these materials, they noticed something interesting about how well they handled temperature changes passively. The material actually has pretty decent insulation properties too, with an R-value reaching around 1.7. Recent research from 2024 looked at thermal expansion issues and found that polycarbonate expands quite a bit when heated, about 0.065 mm per meter per degree Celsius. This characteristic means installers need special joints and connection systems, which has led to some pretty cool innovations in how we put together big building facades today.

Transition From Passive to Active Building Envelopes Using Smart Polycarbonate

Polycarbonate panels today aren't just sitting there anymore they're becoming smart building skins thanks to built-in sensors and those cool dynamic tinting features we see these days. The smart stuff can actually change how much light comes through from about 15 percent all the way up to 80 percent really fast when conditions outside change. And guess what? That means buildings need their heating and cooling systems to work less hard, cutting down on annual HVAC costs by around 23 percent without messing with the nice natural light inside. What we're seeing here is basically a big change in how buildings handle glass. Instead of having plain old static windows, we now get these active envelopes that do more than just look good they actually help save energy and make people inside feel better too.

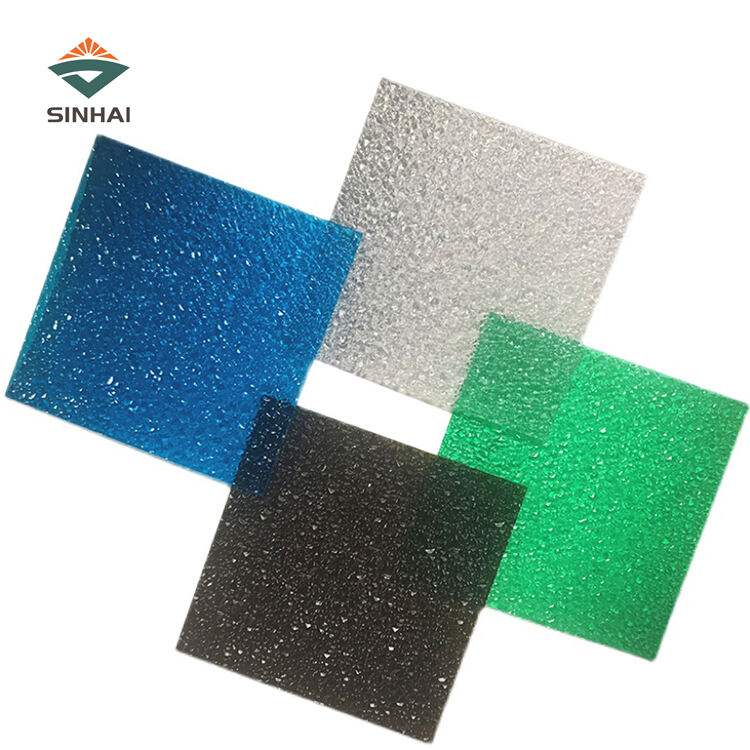

Role of Modern Manufacturing Processes Like Co-extrusion and Embossing Techniques

The co-extrusion process allows manufacturers to combine UV protection, condensation resistance, and structural strength into one panel, which makes things last longer without cutting corners on how well they work. When it comes to embossing, this technique forms those tiny prism-like patterns on the surface that spread light around nicely while still letting through about 87% of the available light. What's really interesting is how these improvements open up possibilities for special orders too. Take fire resistant panels for instance, some meet the tough Euroclass B-s1,d0 standards. And despite all these features packed into them, these panels only weigh 3 kilograms per square meter when they're 16 millimeters thick. That kind of weight to performance ratio makes architects sit up and take notice for all sorts of building projects.

Embedded Intelligence: Integrating Sensors and IoT in Polycarbonate Panels

In-mold structural electronics (IMSE®) technology for seamless integration of electronic functions

IMSE® technology embeds circuits and sensors directly into polycarbonate during manufacturing, eliminating external components that compromise weather resistance. This method preserves structural integrity while enabling touch-sensitive controls, diagnostic monitoring, and other smart functionalitiesâideal for façades requiring both resilience and connectivity.

Embedding IoT-enabled components into polycarbonate for real-time environmental monitoring

IoT sensor arrays integrated into polycarbonate panels monitor temperature, humidity, and air quality in real time. Data is transmitted wirelessly to building management systems, allowing automated adjustments to HVAC and lighting. This integration enhances indoor environmental control and supports predictive maintenance strategies across commercial and institutional buildings.

Case study: Smart greenhouse using sensor-integrated polycarbonate panels for climate control

A 12,000 sq ft greenhouse achieved 23% energy savings using polycarbonate roofing with embedded temperature sensors. When internal temperatures exceeded optimal levels, the system automatically triggered shading and ventilation mechanisms. The optical clarity of the panels supported plant growth, demonstrating how intelligent materials can enhance sustainability in controlled environments.

Challenges in durability and signal integrity under prolonged UV exposure

Despite progress, long-term UV exposure remains a challenge: a 2023 materials study found up to 18% signal attenuation after 2,000 hours. Ongoing research focuses on hybrid encapsulationâcombining UV-resistant coatings with shielded conductive pathwaysâto ensure reliable sensor performance over extended service life.

Self-Cleaning and Photocatalytic Surface Technologies for Sustainable Performance

Self-Cleaning Polycarbonate Panels Through Photocatalytic Technologies

Titanium dioxide (TiOâ)-based photocatalytic coatings break down organic contaminants when exposed to sunlight, generating reactive oxygen species that decompose dirt and pollutants. This self-cleaning mechanism reduces maintenance costs by up to 60% compared to untreated surfaces, according to a 2024 Photocatalytic Surface Engineering Study, while preserving optical clarity over decades.

UV-Protective Coatings and Surface Treatments Enhancing Longevity

Multi-layer UV-protective coatings now block 99.9% of radiation below 400 nm while transmitting 92% of visible light. By preventing yellowing and microcracking, these treatments extend service life beyond 25 yearsâeven in extreme climatesâensuring long-term aesthetic and structural performance.

Trend Analysis: Adoption of Hydrophilic and Anti-Fouling Surfaces in Urban Architecture

More cities are turning to polycarbonate materials that have these special surfaces which do two things at once: they clean themselves through light reactions and attract water instead of repelling it. The industry calls them "smart skins" because they let water run off buildings much faster than regular materials do, sometimes as much as 40 percent speedier. This means less staining problems when acid rain hits or dust settles on surfaces. According to recent data from the Coating Innovations Report released last year, there's been an enormous spike in interest for these kinds of coatings too. Demand has tripled since just a few years ago across train stations, airports, and tall buildings throughout major metropolitan areas. Urban planners point this trend toward stricter regulations about air pollution control measures being implemented in many growing cities around the world.

Dynamic Light and Thermal Control: Thermochromic, Electrochromic, and IR-Selective Systems

Temperature-Responsive Polycarbonate Materials for Dynamic Insulation Performance

Thermochromic polycarbonate panels adapt to ambient temperatures, increasing infrared reflectance by up to 58% when outdoor temperatures exceed 28°C (86°F). Despite this shift, they maintain 82% visible light transmission, functioning as dynamic thermal buffers that reduce cooling demands in variable climates.

Smart Windows with Adjustable Transparency Powered by Electrochromic or Thermochromic Layers

Polycarbonate panels with electrochromic properties work on low voltage to darken surfaces and cut down solar heat gain somewhere around 30 to 40 percent. This gives architects much better control when managing daylight levels and dealing with glare issues in buildings. Studies looking at commercial buildings show these smart glass solutions can save anywhere from 19% to nearly 27% on yearly HVAC costs according to research published in the Smart Glass Efficiency Study. For thermochromic versions, they rely on special coatings made from vanadium dioxide which automatically change from clear to reflective as temperatures hit certain points. The result is this kind of passive temperature regulation that doesn't require any manual intervention once installed properly.

Use of Smart Tints for Balancing Daylight and Shading in Commercial Buildings

Variable-opacity polycarbonate panels are replacing mechanical shading systems in modern office designs. A 2024 industry analysis showed that buildings using electrochromic tints achieved:

| Metric | Improvement |

|---|---|

| Daylight utilization | +34% |

| Glare incidents | -41% |

| Lighting energy use | -28% |

Even in maximum tint mode, these panels retain 74â89% visual clarity and block 92% of UV radiation, ensuring occupant comfort and view preservation.

Near-Infrared Selectivity as a Measure of 'Cool Light' Transmission in Energy-Efficient Designs

Advanced nano-coatings allow polycarbonate to transmit 88% of visible light while rejecting 70% of near-infrared wavelengths (700â1400 nm), delivering âcool daylightâ without thermal load. This spectral selectivity is especially beneficial in retail spaces, where high color rendering (CRI >92) must align with strict thermal comfort requirements.

Enhancing Energy Efficiency and Indoor Comfort Through Advanced Polycarbonate Design

Today's polycarbonate panels bring together smart engineering and cutting edge materials to get the most out of natural light while keeping temperatures stable inside buildings. The multiwall designs let in around 90 percent of available daylight but still manage to cut down on unwanted heat buildup thanks to special coatings that reflect infrared light. Some of these coatings can bounce back as much as 85% of near infrared radiation according to what I've seen in testing. A recent study from Building Physics in 2024 found that all these improvements actually cut down on air conditioning needs by somewhere between 15 and 30 percent when compared with regular glass installations.

Customizable Solar Transmission Properties for Architectural Design Flexibility

Architects can tailor solar transmission coefficients from 0.35 to 0.65 using variable cavity designs and prismatic surface treatments. Tropical hospitals often specify lower values (0.40) to balance patient comfort with UV protection, whereas educational facilities favor higher transmission (0.55+) to minimize reliance on artificial lighting.

Controversy Analysis: Trade-offs Between Optical Clarity and Energy Modulation in Smart Tints

There's still quite a discussion going on within the industry about how to strike the right balance between light diffusion and energy efficiency when it comes to electrochromic systems. Recent testing shows that these smart tint technologies can hold around 72% visibility even when they're modulating solar transmission at about half capacity. But not everyone is convinced. Some folks in the field are concerned about an estimated 3 to 5 percent drop in efficiency each year caused by those pesky UV rays breaking down materials over time. That's where the new wave of nano ceramic coatings comes into play. These coatings promise to tackle the problem head on, making these systems last longer in real world conditions and giving building managers more peace of mind about their investment in smart polycarbonate solutions for windows and facades.

FAQ Section

What are polycarbonate panels commonly used for?

Polycarbonate panels are widely used in architecture for creating greenhouses, building facades, and as smart building skins with integrated technologies for enhanced energy efficiency and indoor comfort.

How do smart polycarbonate panels save energy?

Smart polycarbonate panels save energy by adjusting light transmission in response to external conditions, reducing the need for heating and cooling systems to work hard, leading to significant savings in HVAC costs.

What are the benefits of using polycarbonate panels in architecture?

Benefits include their impact resistance, excellent insulation properties, ability to dynamically modulate light and heat, and the integration of IoT and sensor technologies for improved indoor environmental control.

How do embedded sensors in polycarbonate panels contribute to building management?

Embedded sensors in polycarbonate panels allow for real-time environmental monitoring, temperature, humidity, and air quality data transmission to building management systems for automated adjustment and predictive maintenance.

Table of Contents

- From Passive Glazing to Active Building Skins: The Evolution of Polycarbonate Panels

-

Embedded Intelligence: Integrating Sensors and IoT in Polycarbonate Panels

- In-mold structural electronics (IMSE®) technology for seamless integration of electronic functions

- Embedding IoT-enabled components into polycarbonate for real-time environmental monitoring

- Case study: Smart greenhouse using sensor-integrated polycarbonate panels for climate control

- Challenges in durability and signal integrity under prolonged UV exposure

- Self-Cleaning and Photocatalytic Surface Technologies for Sustainable Performance

-

Dynamic Light and Thermal Control: Thermochromic, Electrochromic, and IR-Selective Systems

- Temperature-Responsive Polycarbonate Materials for Dynamic Insulation Performance

- Smart Windows with Adjustable Transparency Powered by Electrochromic or Thermochromic Layers

- Use of Smart Tints for Balancing Daylight and Shading in Commercial Buildings

- Near-Infrared Selectivity as a Measure of 'Cool Light' Transmission in Energy-Efficient Designs

- Enhancing Energy Efficiency and Indoor Comfort Through Advanced Polycarbonate Design

- FAQ Section