The Shift from Glass to Solid Polycarbonate in Retail Displays

A recent look at commercial design trends by the Ponemon Institute found that around 72% of retail chains are turning to solid polycarbonate sheets for their premium displays these days. Why? Well, polycarbonate keeps that clear glass look most shoppers expect, transmitting about 88% of available light but without all the problems regular glass brings. Retailers know this stuff just makes sense compared to tempered glass, which somehow manages to be responsible for roughly 34% of display related injuries each year. That's why we see so many stores switching to these shatter resistant options, especially in busy spots where people bump into things all the time like shopping malls and brand showcase locations.

Material Advantages: Safety, Weight, and Installation Efficiency

Solid polycarbonate sheets deliver three critical advantages over traditional glass:

- 250x Greater Impact Resistance (ASTM D256 standard)

- 50% Lighter Weight for easier handling and mounting

- 30% Faster Installation due to thermal-forming flexibility

These properties enable retailers to create larger uninterrupted display surfaces while cutting installation labor costs. A 2024 materials study found maintenance costs for polycarbonate displays averaged 40% lower than glass equivalents over 5 years due to reduced breakage and replacement needs.

Case Study: Luxury Retailer Upgrades to Polycarbonate Display Cases

A European jewelry chain replaced all glass display cases with 12mm solid polycarbonate sheets across 120 stores, achieving:

| Metric | Glass (2019-2021) | Polycarbonate (2022-2024) |

|---|---|---|

| Annual breakage incidents | 47 | 0 |

| Energy costs (lighting) | $18.2k | $14.1k (-22.5%) |

| Customer interaction time | 2.3 min | 3.1 min (+34.8%) |

The improved safety profile allowed removal of obstructive protective barriers, increasing product visibility and customer engagement metrics.

Impact Resistance: 250x Stronger Than Glass for High-Traffic Areas

Polycarbonate sheets offer incredible protection for retail spaces, standing up to about 250 times more impact than regular tempered glass according to ASTM D5628 tests. The reason? Polycarbonate has a unique molecular makeup that actually bends when force is applied instead of breaking apart like glass does. Stores with busy entryways or display areas where people gather will find these sheets hold up remarkably well against constant bumps from shopping carts and other everyday accidents. Industry tests have measured their impact resistance at over 26.67 joules, which means they can take a hit similar to what happens when a 5kg object falls from 1.5 meters high without cracking or failing.

Real-World Application: Mall-Based Display Cases with Enhanced Safety

In 2023, researchers looked at 12 different shopping centers across America and discovered something interesting about display cases made from 6mm thick polycarbonate instead of regular glass. These plastic displays broke way less often actually around 92% fewer times than their glass counterparts did. The real benefit became apparent in busy places like food courts and kid zones, where people bump into things all the time accidentally. Store managers who switched over saw their emergency repair bills drop by about four fifths, which saved them serious money. Plus, shop owners noticed that products stayed safer when customers were rushing around buying stuff during holiday seasons or other busy times.

Debunking Myths: Addressing Misconceptions About Polycarbonate Strength

Most people think thinner means weaker when it comes to polycarbonate, but that's simply not true. Studies show that even at just 2mm thick, these sheets can handle impressive tensile strength around 655 kgf per square centimeter. That's actually almost exactly what we see in the much thicker 10mm versions, with only a tiny gap between them (less than 2%). What makes this material so special is how it handles extreme temperatures too. It stays tough and flexible from really cold -40 degrees Celsius all the way up to scorching hot 120°C, which solves those worries about cracks forming in storage facilities where temperature control matters. And let's not forget about those fancy scratch resistant coatings now available. They keep surfaces looking clear and pristine even after thousands upon thousands of cleanings – over 10,000 wipe downs in lab tests!

Optical Clarity and Aesthetic Flexibility of Solid Polycarbonate

Transparency and Light Transmission: Up to 88% Clarity

Polycarbonate sheets come really close to glass when it comes to transparency, letting through about 88% of available light. This makes products behind them stand out clearly in display cases and shop windows. Glass does have slightly better clarity at around 90%, but most retailers actually prefer polycarbonate for their busy stores. Why? Because safety matters more than perfect clarity when customers are constantly bumping into displays. According to a recent material study from 2024, polycarbonate keeps looking clear even when temperatures change throughout the day. Glass tends to fog up when there's condensation, something that happens all the time in grocery stores and malls where temperature control isn't always perfect.

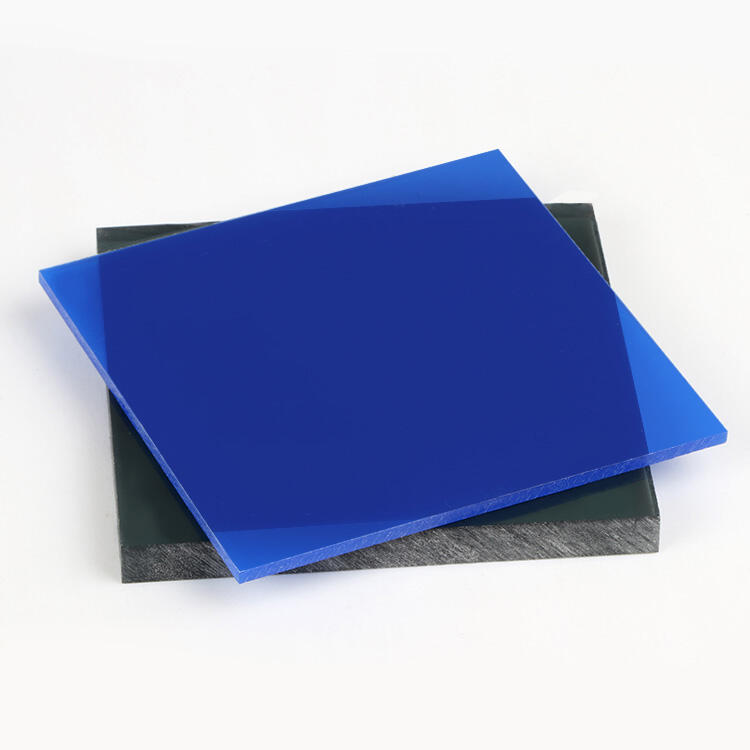

Color and Finish Options: Clear, Opal, Bronze, and Tinted Variants

Manufacturers offer seven standard variants–including opal (diffused light), bronze (UV-filtering), and anti-glare textured finishes–to align with brand aesthetics. Unlike rigid glass customization workflows, polycarbonate sheets support post-installation modifications:

- Tinted sheets reduce 98% of UV wavelengths (380–400 nm) without compromising color fidelity

- Patterned finishes diffuse light evenly, eliminating hotspots in jewelry displays

Balancing Aesthetics and Functionality in Premium Display Design

More luxury shops are now combining 6mm clear polycarbonate sheets with LED lights because they get about 88% transparency which works great for showing off jewelry, plus it's way tougher than regular glass standing up to impacts 250 times better. The material has become popular in both museums and high end boutiques where display cases need to handle all sorts of handling from visitors but still let customers see every detail clearly. Designers love this stuff since it keeps precious items safe during busy events without making the display look cloudy or damaged.

UV and Scratch Resistance: Protective Coatings for Longevity

UV Protection: Preventing Yellowing and Degradation Over Time

Polycarbonate sheets come with special UV resistant coatings that help keep them clear even when used in display cases under both sunlight and store lighting. According to a recent study from Eureka in 2024 looking at self healing materials, these sheets with nano ceramic UV protection can still let through about 90 percent of light after sitting outside for five whole years without fading much compared to regular ones that tend to turn yellow over time. For high end shops where products need to look their best and colors must stay true, this kind of sheet is really worth considering because it maintains that showroom quality appearance so important for attracting customers.

Abrasion-Resistant (AR Clear) Coatings and Performance Data

To address scratch sensitivity, manufacturers apply abrasion-resistant (AR Clear) coatings using plasma-enhanced deposition. Industry analyses show these coatings reduce surface scratches by 72% compared to uncoated polycarbonate. Performance metrics include:

| Coating Type | Scratch Resistance (Mohs Scale) | Warranty Period |

|---|---|---|

| Standard AR Clear | 4H | 5 years |

| Premium AR Clear | 6H | 10 years |

Coating Trade-offs: Balancing Cost, Scratch Resistance, and Clarity

While thicker coatings improve scratch resistance, they reduce light transmission by up to 5% and increase material costs by 15–30%. Retailers prioritizing aesthetics often opt for mid-range AR Clear coatings (85% clarity retention, 8-year lifespan), which strike a balance between upfront investment and long-term maintenance costs.

Industry Challenge: High Impact Resistance vs. Surface Scratch Sensitivity

The inherent flexibility that makes solid polycarbonate sheets 250x more impact-resistant than glass also increases susceptibility to fine scratches–a trade-off mitigated through coatings rather than material redesign. Ongoing R&D focuses on hybrid polymer formulas to address this duality without compromising optical performance.

Design Versatility and Customization with Solid Polycarbonate Sheets

Custom Display Cabinet Design: Bending, Cutting, and Forming On-Site

Solid polycarbonate sheets give retail designers a whole new level of creative control because they can work with them right on site. Traditional materials need special factory treatments, but these polycarbonate sheets bend cold at angles as sharp as 135 degrees using nothing fancy than regular woodshop equipment. Fixture installation tests show this process takes about 55 percent less time compared to working with tempered glass. Many designers have noticed their labor costs drop between 30 to 45 percent when they apply simple DIY methods instead of relying on outside specialists for complex installations.

- Precision cutting for curved cabinet profiles

- Heat-free bending for angular display risers

- Edge-polishing for seamless premium finishes

Rapid Prototyping and Modular Display Solutions Using Polycarbonate

The material’s compatibility with laser cutting (0.1mm tolerance) and CNC routing enables same-day prototyping for seasonal displays. A leading European retailer reduced display refresh cycles from 3 weeks to 4 days using 8mm polycarbonate sheets and modular interlocking components–70% reusable across campaigns.

Growing Adoption in High-Traffic Stores and Interactive Exhibits

Airport duty-free shops now favor solid polycarbonate for security-enhanced displays, with impact resistance preventing 92% of accidental damage claims (retail safety audit data). Interactive museum exhibits benefit from the material’s 85% lighter weight versus glass, enabling touchscreen integrations without structural reinforcement.

Future Trends: Smart Integration and Sustainable Display Innovations

Emerging applications embed UV-responsive privacy films and anti-microbial coatings directly within polycarbonate layers. Closed-loop recycling pilots recover 97% of material waste for recasting, aligning with LEED v5 sustainability targets for retail construction.

FAQ

Why are retailers switching to polycarbonate sheets instead of glass for display cabinets?

Retailers are switching to polycarbonate sheets because they offer high impact resistance, safety, and lighter weight compared to glass. They also allow for faster installation and cost savings in maintenance.

How does polycarbonate compare to glass in terms of light transmission and visibility?

Polycarbonate sheets transmit about 88% of available light, close to glass's 90%. This makes them ideal for display cabinets where product visibility is crucial.

Are polycarbonate sheets suitable for high-traffic retail environments?

Yes, polycarbonate sheets are perfect for high-traffic areas due to their superior impact resistance and durability compared to glass, significantly reducing breakage incidents.

What are the customization options available for polycarbonate sheets?

Polycarbonate sheets come in various finishes including clear, opal, bronze, and tinted variants. They support on-site modifications like bending, cutting, and forming, allowing for a range of custom designs.

How do polycarbonate sheets perform in terms of UV resistance?

Polycarbonate sheets are coated with UV-resistant materials, preventing yellowing and maintaining optical clarity even under prolonged sun exposure or store lighting.

Table of Contents

- The Shift from Glass to Solid Polycarbonate in Retail Displays

- Material Advantages: Safety, Weight, and Installation Efficiency

- Case Study: Luxury Retailer Upgrades to Polycarbonate Display Cases

- Impact Resistance: 250x Stronger Than Glass for High-Traffic Areas

- Real-World Application: Mall-Based Display Cases with Enhanced Safety

- Debunking Myths: Addressing Misconceptions About Polycarbonate Strength

- Optical Clarity and Aesthetic Flexibility of Solid Polycarbonate

- UV and Scratch Resistance: Protective Coatings for Longevity

- Design Versatility and Customization with Solid Polycarbonate Sheets

- Custom Display Cabinet Design: Bending, Cutting, and Forming On-Site

- Rapid Prototyping and Modular Display Solutions Using Polycarbonate

- Growing Adoption in High-Traffic Stores and Interactive Exhibits

- Future Trends: Smart Integration and Sustainable Display Innovations

-

FAQ

- Why are retailers switching to polycarbonate sheets instead of glass for display cabinets?

- How does polycarbonate compare to glass in terms of light transmission and visibility?

- Are polycarbonate sheets suitable for high-traffic retail environments?

- What are the customization options available for polycarbonate sheets?

- How do polycarbonate sheets perform in terms of UV resistance?