Impact Resistance and Structural Strength Compared

When comparing Plexiglass vs Polycarbonate, impact resistance reveals stark differences. Material scientists measure this through toughness—the ability to absorb energy before fracturing. Polycarbonate dominates this category, offering unparalleled protection against sudden force.

Polycarbonate’s Superior Impact Absorption (250× Acrylic)

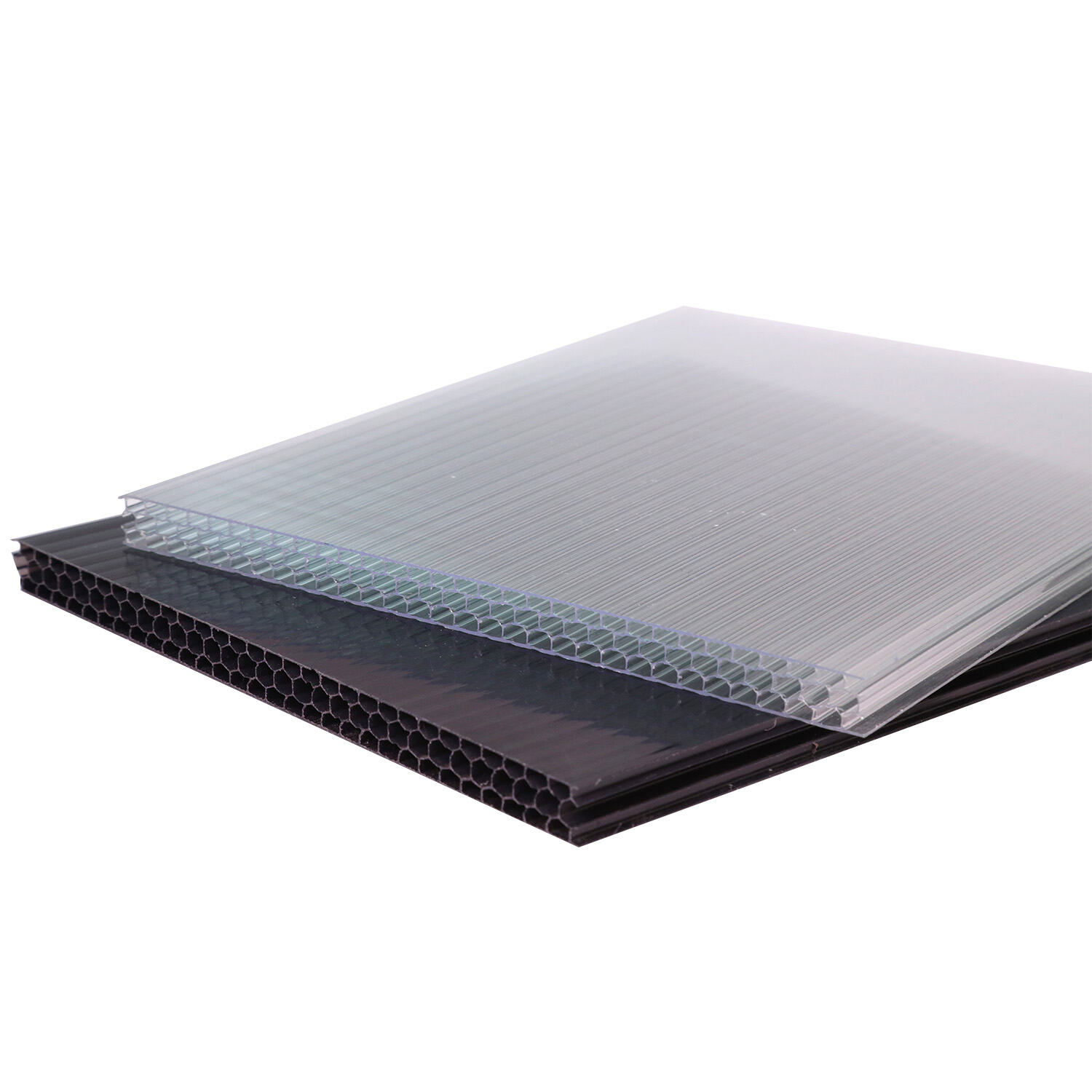

When it comes to absorbing impacts, polycarbonate is way ahead of Plexiglass by about 250 times because of how flexible its molecules are at a microscopic level. Regular old Plexiglass has these stiff acrylic chains running through it, but polycarbonate actually stretches when something hits it, kind of like a trampoline spreading out force instead of letting everything crash through. That's why we see it used so much in places where breaking glass would be dangerous stuff like those big shields cops wear during protests or special windows meant to hold up against hurricanes. Some lab work backs this up too - they tested sheets half an inch thick and found that polycarbonate held up under repeated hammer blows while acrylic just shattered right away. And here's another thing about it compared to other materials that break easily: instead of cracking completely, polycarbonate bends a little first then snaps back into shape, which means whatever structure it's part of stays intact even after getting hit hard.

How Breakage Behavior Differs: Brittle Fracture (Plexiglass) vs Ductile Deformation (Polycarbonate)

When put under pressure, Plexiglass tends to break in a brittle way, kind of like when chalk snaps suddenly without much bending first. What happens is that this rigid material basically shatters into those sharp little pieces once it reaches its breaking point. On the flip side, polycarbonate acts quite differently. Instead of cracking right away, it stretches out quite a bit, sometimes even up to 130 percent longer than its original size before finally giving way. This stretchy quality comes from how the plastic molecules move past each other instead of just snapping apart. Take for instance what happens when a baseball smacks into Plexiglass versus polycarbonate. With Plexiglass we get those star shaped cracks radiating outwards, but polycarbonate just takes the hit and forms a dent. Because of this ability to stretch, engineers can design specific areas in safety equipment where controlled failure occurs, absorbing impact forces without creating dangerous fragments all over the place.

Environmental Durability: UV Stability, Thermal Performance, and Weather Resistance

When selecting between Plexiglass vs Polycarbonate for outdoor applications, environmental durability becomes critical. Both materials face degradation from UV radiation, temperature extremes, and moisture—but their resilience differs significantly.

UV Resistance and Clarity Retention Over Time

Plexiglass, also known as acrylic, naturally stands up to UV damage pretty well. Most samples keep around 90% of their original clarity even after sitting outside for a decade without any special treatments. Polycarbonate material is definitely tougher when something hits it, but it has a big downside. Left unprotected, these panels start turning yellow fast when exposed to sunlight. We've seen cases where uncoated polycarbonate loses about 15% of its light transmission within just two years, which makes everything look hazy and cloudy over time. That's why many people still prefer Plexiglass for things that need to stay clear over the long haul, especially stuff like greenhouse windows or outdoor signs. The fact that it doesn't require constant maintenance saves money in the long run despite being slightly less impact resistant than polycarbonate.

Temperature Limits: Cold Embrittlement, Heat Distortion, and Service Range

When it comes to handling extreme temperatures, polycarbonate really stands out. It works reliably across a wide range from minus 40 degrees Celsius all the way up to 120 degrees without cracking or breaking. This material stays flexible even in freezing conditions which makes it great choice for things like parts inside freezers or car components that need to function properly in very cold weather. Plexiglass has its limits too. While it holds up reasonably well until around 80 degrees Celsius, it starts getting brittle when temps drop below minus 20 and actually begins to warp if exposed to anything over 70 degrees. That's why we see polycarbonate being used so much in places where heat is a concern such as outdoor lighting systems or equipment installed in hot desert regions. The difference in performance between materials shows clearly when looking at their deflection temperatures. Polycarbonate can handle deformation at 135 degrees while regular acrylic only manages about 95 before starting to lose shape.

| Property | Plexiglass (Acrylic) | Polycarbonate |

|---|---|---|

| UV Resistance | Inherently stable | Requires coating |

| Max Service Temp | 80°C | 120°C |

| Min Service Temp | –20°C | –40°C |

| Clarity Loss (10y) | <10% | Up to 40% (uncoated) |

For applications prioritizing weather resistance, polycarbonate’s thermal range and impact tolerance suit dynamic environments, while Plexiglass offers superior clarity retention with minimal upkeep.

Surface Durability and Maintenance Requirements

When comparing Plexiglass to polycarbonate, how well materials hold up against daily wear really matters for their lasting value. Polycarbonate takes hits better than most, but what makes acrylic stand out is its ability to resist scratches thanks to its unique molecular makeup. According to recent studies from the Plastics Engineering Handbook published last year, acrylic generally scores between 85 and 90 on the Rockwell M hardness scale, whereas polycarbonate only reaches around 70 to 75. Because of this difference in hardness, acrylic stays clear and see-through much longer when exposed to regular touching and rubbing. The downside though? Acrylic needs gentle treatment since it can crack suddenly if mishandled, unlike the more forgiving nature of polycarbonate.

Scratch Resistance: Why Plexiglass Scores Higher Despite Lower Impact Strength

The reason acrylic stands up better to those tiny scratches from everyday dust and cleaning products is because of how closely packed its polymer chains are, creating a tougher surface overall. Polycarbonate takes a different approach though its ability to withstand impacts actually stems from those flexible molecular bonds which soak up shocks but leave behind dents much easier than acrylic does. When looking at things like display cases in museums or store signs where looks really count, most people find that acrylic's resistance to scratching makes all the difference despite being somewhat less tough when hit hard. Keeping these materials looking good requires regular care with microfiber cloths specifically since they help avoid those small abrasions that gradually make surfaces look cloudy and worn out after months of use.

Chemical Compatibility and Cleaning Best Practices for Each Material

| Material | Avoid | Recommended Cleaners |

|---|---|---|

| Acrylic | Ammonia, solvents | Mild soap, isopropyl alcohol (70%) |

| Polycarbonate | Strong alkalines, acetone | Water, pH-neutral detergents |

Acrylic degrades when exposed to solvents like acetone, while polycarbonate withstands gasoline and oils but clouds with alkaline cleaners. For both materials, abrasive pads cause permanent damage. Best practices include immediate spill cleanup and specialized plastic polishes for scratch remediation every 6–12 months in high-traffic environments.

Plexiglass vs Polycarbonate: Matching Material Properties to Real-World Applications

When choosing between acrylic (also known as Plexiglass) and polycarbonate materials, the decision really comes down to what each material can handle versus what the project actually needs. Polycarbonate stands out because it won't break easily even when hit hard. Some tests show it can withstand impacts about 250 times stronger than regular acrylic. Plus, it works well in extreme temperatures ranging from minus 40 degrees Celsius all the way up to 120 degrees Celsius. That makes polycarbonate great for places where safety matters most, think things like bulletproof windows at banks, protective gear during protests, or those thick transparent covers on industrial machines. On the flip side, acrylic has something going for it too. It doesn't get scratched so quickly and lets through almost 92 percent of available light. For projects where clear visibility is important and surfaces need to stay looking good over time, acrylic becomes the better choice. Retail stores often use it for product showcases, museums display valuable items behind acrylic glass, and architects sometimes incorporate it into building designs where both beauty and protection are needed.

- Structural & Safety Applications: Polycarbonate dominates where fracture resistance is paramount—its ductile deformation absorbs extreme forces without shattering.

- Aesthetic & Light-Duty Uses: Acrylic excels in signage, aquariums, and point-of-sale displays where scratch resistance maintains visual appeal.

- Environmental Demands: Polycarbonate withstands outdoor weathering when UV-coated, while acrylic resists yellowing and thermal expansion.

Matching these materials to operational stresses—whether impact loads, temperature swings, or surface wear—ensures optimal performance and cost efficiency across industries.

FAQ: Plexiglass vs Polycarbonate

What is more impact-resistant, Plexiglass or Polycarbonate?

Polycarbonate is more impact-resistant than Plexiglass, offering superior protection against sudden force and maintaining structural integrity after impacts.

Which material is better for outdoor use, Plexiglass or Polycarbonate?

Plexiglass is generally better for outdoor use if clarity retention over time is the priority, as it withstands UV exposure better. Polycarbonate is also suitable for outdoor conditions but may require a UV protective coating.

Are there scratch resistance differences between Plexiglass and Polycarbonate?

Yes, Plexiglass tends to resist scratching better than Polycarbonate due to its dense molecular makeup, making it a favored choice for aesthetic applications where surface preservation is important.

Table of Contents

- Impact Resistance and Structural Strength Compared

- Environmental Durability: UV Stability, Thermal Performance, and Weather Resistance

- Surface Durability and Maintenance Requirements

- Plexiglass vs Polycarbonate: Matching Material Properties to Real-World Applications

- FAQ: Plexiglass vs Polycarbonate