Understanding Polycarbonate’s Natural UV Absorption and Limitations

Polycarbonate (PC) offers inherent UV protection due to its molecular structure. Aromatic rings in its polymer chains absorb UV radiation below 320 nm, blocking over 99% of UVB and 95% of UVA rays—outperforming many untreated transparent materials in initial UV blocking capacity.

Molecular Structure and Inherent UVA/UVB Blocking Threshold

The carbonate groups and benzene rings in PC act as chromophores that absorb high-energy UV photons. This absorption occurs across critical shortwave spectra:

- Complete UVB blocking (280–315 nm)

- Partial UVA absorption (315–400 nm)

Even thin 1 mm sheets provide substantial protection, making PC initially effective for UV-sensitive applications without additives.

Why Uncoated Polycarbonate Degrades: The Role of Photooxidation

When UV rays get absorbed by polycarbonate that's not protected, it starts a process called photooxidation. What happens next is pretty interesting at the molecular level. The energy from those rays actually breaks apart chemical bonds in the material, creating these unstable particles known as free radicals. These radicals then team up with oxygen from the air around them. The result? A whole cascade of reactions that lead to several problems. First comes chain scission where long polymer chains start breaking down. Then there's the yellowing effect as new bonds form between molecules. And finally, the surface gets brittle with tiny cracks forming all over. After spending just a couple of years under the sun, plain old PC without any coating might lose nearly half its tensile strength while developing that cloudy appearance we all know too well. That's why manufacturers need to think about adding protection if their products are going to last outdoors.

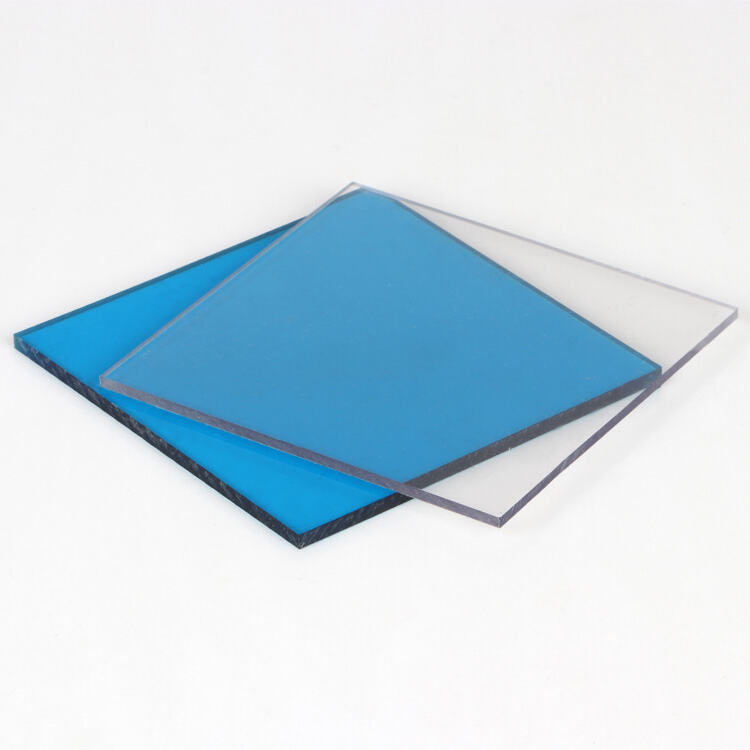

Enhancing UV Protection: Coatings and Manufacturing Techniques

Co-Extrusion, Surface Coatings, and UV-Stabilizer Blending Compared

Three primary methods enhance UV resistance in polycarbonate, each with distinct advantages and limitations:

- Co-extrusion applies a permanent UV-blocking layer—typically acrylic or fluoropolymer—during extrusion. This integrated approach blocks 99% of UV radiation while maintaining optical clarity and is ideal for architectural glazing requiring decades of durability. However, it requires specialized equipment, increasing production costs by 15–25%.

- Surface coatings, such as silicone hardcoats, are applied post-manufacturing via spray or dip processes. They offer flexibility for complex geometries and lower initial costs but degrade faster through abrasion or weathering—often requiring reapplication within 5–7 years in high-sun regions.

- UV-stabilizer blending incorporates additives like HALS (Hindered Amine Light Stabilizers) directly into the polymer melt. It ensures uniform protection throughout thick sections—ideal for injection-molded automotive components—though concentrations above 3% may reduce impact strength or cause slight yellowing.

Co-extrusion excels in permanent outdoor installations; coatings balance cost and adaptability; and blending optimizes performance in mass-produced, intricate parts. Each method extends product lifespan by 10–20 years compared to untreated polycarbonate by mitigating photooxidation.

Testing UV Resistance: Methods and Industry Standards

Accelerated Weathering Tests: Simulating Years of UV Exposure

Weathering tests that speed things up can pack decades worth of UV damage into just a few weeks. These tests happen in special chambers where UV lamps mimic sunlight along with humidity cycles to create those harsh outdoor conditions we all know about. There are industry standards like ASTM G154 and ISO 4892-3 that lay out exactly what kind of UV light and moisture levels should be used during testing. Take the common 1,000 hour test for instance it usually matches around 2 to 5 years of actual exposure outside, though this varies based on how severe the local climate is. This kind of testing gives manufacturers confidence before products hit the market that they'll stand up against UV damage over time.

Key Performance Metrics: ΔE Color Change, Gloss Loss, and Tensile Retention

Three metrics quantify UV degradation:

- ΔE (Delta E): Measures color shift via spectrophotometry; values above 2.0 indicate visible yellowing.

- Gloss retention: Tracks surface reflectivity loss; premium UV-protected polycarbonate retains >85% gloss after 5-year equivalent exposure.

- Tensile strength retention: Critical for structural integrity; industry benchmarks require >70% strength preservation post-testing.

These metrics collectively validate whether UV-blocking treatments meet durability thresholds for outdoor applications.

Benefits of UV-Protected Polycarbonate in Outdoor Applications

Long-Term Durability, Anti-Yellowing, and Performance in Glazing, Roofing, and Signage

Polycarbonate with UV protection lasts much longer outdoors because it fights off photooxidation, which is basically what causes most materials to break down over time. The latest tech includes things like co-extruded layers and special additives that stop more than 99% of harmful UV rays from getting through. Tests show these materials can keep their strength for around 10 to 15 years even when exposed to extreme weather conditions. What's really important for many applications is how this protection prevents yellowing. After being outside for a whole decade, the color change stays below 3 on the Delta E scale, so the material looks almost as clear and attractive as new, which matters a lot in applications where appearance counts.

The material’s impact resistance—200× stronger than glass—synergizes with UV stability to excel in critical applications:

- Glazing: Greenhouse panels and skylights retain light transmission without cracking or haze

- Roofing: Sheets withstand hail and thermal cycling while blocking infrared heat

- Signage: Graphics resist fading despite direct sun exposure

By preventing embrittlement and discoloration, UV-protected polycarbonate reduces replacement costs by up to 40% compared to untreated alternatives—making it a cost-efficient solution for architects prioritizing durability.

FAQ Section

Why does polycarbonate naturally absorb UV radiation?

Polycarbonate absorbs UV radiation due to its molecular structure, particularly the aromatic rings which block UV radiation below 320 nm.

What causes uncoated polycarbonate to degrade?

Uncoated polycarbonate degrades due to photooxidation, where absorbed UV rays break chemical bonds leading to yellowing, brittleness, and a loss in tensile strength.

What is co-extrusion and how does it improve UV protection?

Co-extrusion involves applying a UV-blocking layer during extrusion, enhancing UV protection while maintaining clarity suitable for long-term architectural applications.

How does accelerated weathering testing work?

Accelerated weathering tests use UV lamps and humidity cycles to simulate years of sun exposure in weeks, ensuring products can withstand UV damage.

What are the benefits of using UV-protected polycarbonate?

UV-protected polycarbonate is more durable, resists yellowing, and maintains structural integrity, reducing replacement costs and enhancing outdoor applications.