Ukukhetha Izixhobo Ezilungileyo Zokunciphisa I-Sheets Ze-Polycarbonate

I-Table Saws vs. I-Circular Saws vs. I-Band Saws: Ukucaciswa, Ukulawula Ukutshisa, Nokwebo Kwesikweletu

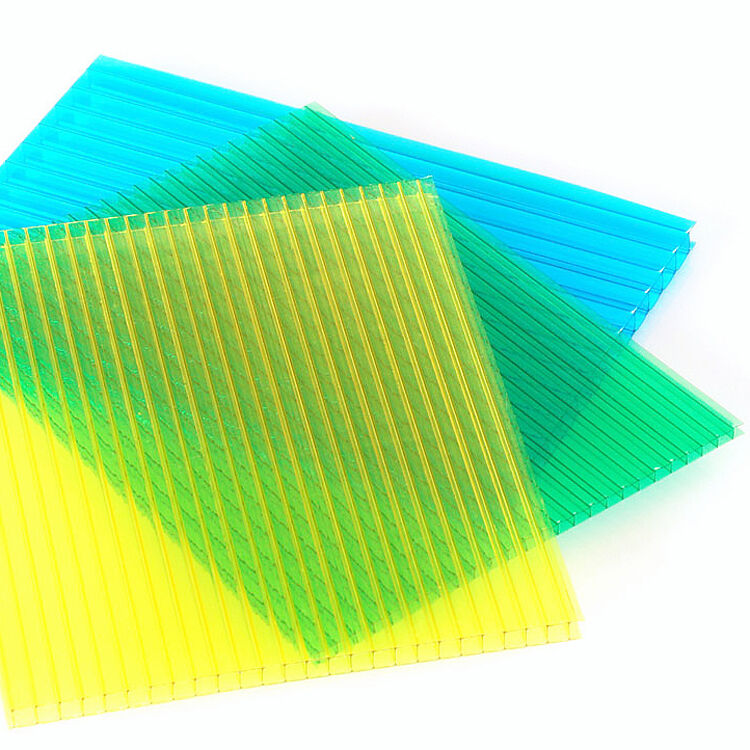

Xhengisa ukuba udlulisa izikrwekwe ezivuthiweyo kumaphepha apolycarbonate, izihlalo zokugcina ziyinxenye eqinile kakhulu xa kufingqwa ubumnandi nokuthola imigqa embalwa. Kodwa kudinga inkxaso eqinile yomlando ukuze ungavukele ngexesha lokugcina. Izicathulo zocingo zifuneka kakhulu kumaphepha amakhulu ngoba mafumaneka, nakuba kukho into ebalulekileyo okufuneka uyicinga ngayo ngokukhawuleza kwesipheya. Abaninzi bafuna ukunciphisa ku-3,000 kuze kube ku-3,500 RPM ukunceda ukulungiswa kwephlatici ngoko konke okuqukumbeko kokwanda. Izipheya ziband saws ziyasebenza ngokunyaniseka kumaphepha athandabuzekayo angaphakathi kwe-8 ne-12 mm. Ukuxhasa kweyesipheya kunye nokungabi khange kangaka kwindawo eyodwa kuthetha ukuba kungaphantsi kokuchithwa kwemigqa. Kubonke abanelanga ngezinto ezi, iisipheya enezibhamu ezingaphaya ezingama-80 kuze kube ma-100 kwaye zenziwe ngendlela ephindaphindwayo ibonakala ngaphezulu ekunciphiseni ukugcinwa kwamandla. Kunye nokuba ungaxoleke ububanzi bekerf. Ukuyiqhuba phantsi kwe-2 mm kuthetha yonke into xa ucina iindlela zomgca okanye ukwenza imigqa engcono ngaphandle kokesipheya okungaqhubi.

| Isiphumo | Ukuphucumana | Ukulawula Isishunxu | Ubunzima bomgca | Kubalulekile kuma |

|---|---|---|---|---|

| Isawuthabhu | Kunye | Kancane | Esikhathini | Amancambo amade amanduli |

| Isawu yesikreli | Umkalo | Kubalulekile* | Ukuhlanganiswa | Amancambo amakhulu amathathakatha |

| Isawubhanda | Umkalo | Kunye | Phansi kwezincwadi | Amaphorma amakhulu/amakhazimula |

| *Kudinga ukulawula iRPM |

Amajikisazi nezixhobo ze-CNC zokukhupha okungcwele noma okuncanyiweyo—Xa ukuthulwa kususemthethweni ixesha lokumisa

Izibhamu zezikhashana ezincane phakathi kwe-10 kunye ne-14 izinto ngosuku bezinkulu zifuna kakhulu ukwenza iindlela ezivuthayo, nokuba zidinga ukubekwa kahle ukuzama ukuvikela iimicro cracks eziphila kwi-vibrations. I-CNC routers ingcono kunezikhundla ezingaphantsi kwe-millimeter kwizigaba ezincanyiweyo, kodwa makwenzekani, ukulayisha kunyusa ixesha elingu-15 kuze kube ngu-30 imizuzu ngaphambi kokuchithwa kusenza. Xa usebenzela into engaphantsi kwezintathu ezimbini zokukhupha, sebenzisa izixhobo zegolide ngoba zingcono ngokushesha. Kodwa xa usaphinda leli xesha, ukuya ekusebenzeni kukunyanisekileyo ngoba izixhobo ze-CNC ziphumaza amaphutha okulinganiso ngaphezu kwezintathu ezimbini kunokuba wenza konke ngohand according to recent studies in Plastics Fabrication Journal. Kwaye khumbula ukuthatha izibhamu ezikhupha phezulu yonke into esinokuyifumaneka, ezi zikhusela iisheets ukuba singakhuphi phezu kwaye iindlela zingasuka xa uqala ukukhupha.

Ukuvula Iblade Namasethingi Okugcina Ukukhupha Kwamapoli Khabhonethi

Umjiko Wezinto, Ububanzi Bekhafu, Nokushisa Kokunyuswa: Ukwakha Kulahleka, Ukuchithwa, Nokukhulwa Kwesithuthwane

Xa usebenzisa i-polycarbonate, izimoto ezinamandla e-carbide ezenziwe ngokulinganisa kwezinto ezintathu azidingeki kuphela kodwa zazingcono. Ukulungiswa okukhethekile kukusiza ekunqumeni izinkomba futhi kushayelela ukugaya kwezinto phakathi kwemigqa yezinto, lokhu kuyakugcina kube lula ngexesha lenkohlaka. Kuzingxenye ezindele ukuya ku-inches ezihlanu (ngaphezu kuka-12.7 mm), londoloza ububanzi bekerf ku-2.5 ukuya ku-3 mm. Ukuba ububanzi buhle beshiwo kungenza imiba yokudluliswa uma isivinini sesayo siyisiseko. Abantu abaningi bathola impumelelo xa basebenzisa izivinini ezingu-10 ukuya ku-15 feet ngeminithi xa bezondeza nezinto ezingu-3 mm. Sebenzisa inkinobho engaqedi ngizonke inkohlaka ukuze ungahlawule maba emelene ngenkohlaka njengoba ushindile kakhulu noma uvale izinkomba xa uhamba ngokushesha kabangani. Xa izinto ziphakeme kakhulu, khumbula ukusa izivinini ngama-20% ngalokho okungeziwe ku-3 mm. Ukulungisa kwizixhobo kwenza uhlelo olukhulu futhi: izixhobo ezilungileyo ziyakusa izinkinga ezivame ekuthuthukiseni ngama-40% kunazo amandla aphathekayo asebenzayo.

Izinqumo ze-RPM kanye nesivinini ngokulinganisa nokuphakama (3—12 mm) ukwenzela ukuncipha kokwenza kwamandla

Kufanele kube yisilinganiso se-RPM esilinganiselwe ngokuphakama kwegolide—akulapho kuphela imoto—ukuphatha ukunakekelwa kwamandla. Izinxenye ezincane zihlukanisa amandla kakhudlwana, ekuvumela izivinini ezide; igolide ephakeme kudinga i-RPM encane ukuze kugcinwe ubushushu obungahleli okuphazanyayo noma ukubanda kwesayizi:

- izigaba ze-3—6 mm : 8,000—10,000 RPM ngezinye ziphazanyo ezide kakhulu

- izigaba ze-8—10 mm : 5,000—7,000 RPM ngeziphazanyo ezilungile, ezithintekayo

- izigaba ze-12 mm : 3,000—4,500 RPM ngeziphazanyo ezincane, ezingahlengi

Lapho sisebenza ngamashidi e-polycarbonate, sibona ukuthi i-RPM yehla cishe ngo-55% uma isuka ku-3 mm iye ku-12 mm ngoba le nto ayiqhubi kahle ukushisa. Qapha ama-chip akha phakathi nemisebenzi yokusika. Amashidi ahlanzekile, acacile asho ukuthi konke kuhamba kahle. Kodwa uma siqala ukubona izinto ezihlanganisiwe noma izinto eziqinile ziqhekeka, lokho kuyisibonakaliso esiyisixwayiso sezinkinga zokushisa ngokweqile. Qiniseka ukuthi ubulala uthuli olwakheke ngomoya onomfutho njalo lapho kunesikhala emsebenzini. Izinsalela zamasimbi zinamathela njengesivakashi esingafuneki, zisebenza njengento ekhuhlayo nevikelayo okwenza izindawo zishise ngokushesha kunalokho obekulindelekile. Ochwepheshe basensimini babika ukuthi cishe izingozi ezine kwezinhlanu ezibangelwa ukushisa zibangelwa isivinini esingalungile kanye namazinga okudla asetshenziswa ndawonye.

Inqubo Yokusika Izinyathelo Ngezinyathelo Yokuveza Amapuleti E-Polycarbonate Angenaphutha

Ukulinganisa, Ukubeka Amamaki Nokuqinisa Izindlela Ezinhle Zokuqeda Ukuhlanekezela Nokungaqondani

Ukufumana imiphumela emihle kusasa ngaphambi kokuba iblade ithintele yini. Okokuqala, thatha uhlelo oluhle lomjikili ohleliwe ngempela kule job. Xa ushaya indawo ofuna ukuthinta kuyo, sebenzisa ngokudla kumgco ophathelene wefilimu esivikelwe ngayo umfanekiso. Sebenzisa imaki yesiqingatha esincane engazange ishiye amashushu okugcina, kahle ungasebenzisi izinkawu ezijwayelekile noma iimaki ezenziwe ngamagugu angaphathi amagugu angavamile njengoko awuthinta umfanekiso. Sebenza ngokuphelele ukuqinisekisa konke okulinganiswe kumaphepha noma amatripyuli. Izimiso ezenziwa phezu kwalokho akunakwenzeka ukulungisa uma kutentha kusenziwe. Ukutenta okulungele kumele kube nemthelela ethile futhi. Sabela into eyodwa njenge-aluminum level noma irula elikhulu le-steel ngokushesha kule nqaku eqoshelwe, bese uyayibamba ngokuphelele. Ungalindeki nezigidi ezincane zokucopheleka xa kubeka ingcinaba ngexabiso lokutenta.

Umkhondo wokubamba kuyisidingo esibalulekile ekugcineni kwemigqa:

- Sebenzisa izikhumba ze-wood noma izikhangala ezizinzileyo zokugcina ukuhla ngokulinganayo kwaye ungavimbele umlando.

- Faka izikhangala kumjane wamanzi angama-6 kuwo-meyo kodwa ngaphandle kwangoko ekupheleni komgca wobude—ukunciphisa ukuthembeka ngaphandle kokulahlekelwa kwendlela.

- Qinisekisa ukuthinta okuphelele kusayizi esilungele, engasengabaleki; konke okuphakanyayo okungaphezulu kuma-inchi ayi-2 kuthintela ukuguqulwa, ukungqinelana, nokungaqondakali kwemeko ngexesha lokunika.

Ukungagcinwa kakubi kuthintela amacutu athintekayo, ukucindezelwa kwesahluko, nokungashiswa okufihlake emva kwezikhathi ezimbalwa emva kokuchitha. Ukugcina ngendlela efanelekileyo kukhangelela ubunzima bokulingana kwaye ukuxhasa ukulahleka okulinganayo kwegazi—zombini ziyinxalenye ephambili yezahluko ezicacileyo, eziphumelelayo.

Iindlela Ezibalulekileyo Zokholoxa Xa Kuchithwa Iisheya Ze-Polycarbonate

Ukuphepha Kwezinyo, Yenkalo, Ne-Inhalation: Ukulungiselela Ukugcwalisa Okuncinci, i-VOCs, Ne-Fumes Ezenziwano

Xa kunciphisa izinto zika-polycarbonate, abasebenzi baphakanyiswa kumzimba ophephilelwa ngamapartikili amancane ekhishwa ngexesha lenkqubo. Le mpapartikili ngu-3 microns nje okanye mncinci kunazo, bakhala iifuyile ezinezizwe ezingaphezu kwe-150 degrees Celsius, apho amagunya ayingcingiyo njenge-styrene ayinjelisa ubomi phakade nangaphandle koko. Izixhobo zokuphepha kumele kube khona ngokuphambene. Abasebenzi kufuneka babe neegoggles eziqinisekisiweyo ze-ANSI Z87.1 enezihlambi zezandla zonke izolo, kwaye babe neeglof zika-nitrile ukuze vikeleke ukuthintana kwesono ngezinto ezisityalo ezisemgangathweni. Kukuphepha kwe-intlungu, iimaski ze-N95 eziqinisekisiweyo zi- NIOSH zilungiselela ngaphaya kwe-95% yezinto ezithintelwayo, kodwa azizange ziphathe xa zingafaniyo nokuba zitshintshwe ngexesha elithile. Iintsolobalelo zibonisa ukuba abantu abasebenzayo kumzidumbu apho le dust ayichanekanga kakuhle bayasikhala kangcono. Inxalenye engu-2022 ye-Occupational Safety Journal yabonisa ukongeza okulinganayo kwe-34% kwiindlela ezinxulumene nokuphephela kwindalo. Xa izizwe ziphakama, konke okuninzi kukudingeka. Amacarti yesitsulo se-organic vapour sisebenza ekulungiseni le VOCs ezithintelwayo. Amava afaka imithombo yokuphepha eyenziwe ngokucacileyo eyihlanseleyo, isono, nendalo ibona imiphumo emininzi. Ngokwamaculo we-Industrial Safety Council woxesha lwasekhohlo, lo mthombo othunyelwayo uphazanya ngokuthe ngqo nge-72%. Lokhu kwenza izixhobo zokuphepha echanekileyo zibe nzima ukuba ziqwalaselwa kumntu ongasebenzisa izinto zika-polycarbonate ngendlela eqinisekileyo.

Imibuzo Evame Ukubuzwa

Izixhumanisi zikuphi okuhle ekugcineni izitiqa ze-polycarbonate?

Izihlalo zethableli zihle kakhulu ekugcineni okuphelele, okude nokuthambile. Izihlalo zekhandela zibaluleke kangako ekugcineni okukhulu noma kwezimali, ngelixa izihlalo zebhendi zisebenza kahle kumazitha amakhulu nezimo eziphucukileyo.

Kungani ukubamba isivinini se-RPM kubalulekile xa usebenzisa izihlalo zekhandela kumazitha we-polycarbonate?

Ukubamba isivinini se-RPM siyisidingo lokukhokha ukuthi ipolasiya ye-polycarbonate igqugquzele ngokushesha kusuke kwenzeka umthwalo wengcinazo lapho kugcinwa.

Ngani angakwenzani ukukhipha ngemva kokugcina polycarbonate?

Ukusebenzisa izihlalo ezinezinkunkuma ze-carbide ezenziwe ngendlela eyathathu, ngokunye nesilinganiso esifanelekile sokugcinwa nobude bokulayisha, kunciphisa ukukhipha.

Izipi zokuphepha zikuphi ezilungile ekugcineni izitha ze-polycarbonate?

Kufanele kube khona izicathulo ezivumelekileyo ANSI Z87.1, izimvudumvudu zenitrile, nezicathulo ze-N95 ukuze kukhokhelwe kakade, ngelinye nalezi ziphuzo ze-organic vapor ukuze kube nzima kakhulu ekukhokheni kwe-VOCs.

Uhlu Lwezinto Eziqukethwe

- Ukukhetha Izixhobo Ezilungileyo Zokunciphisa I-Sheets Ze-Polycarbonate

- Ukuvula Iblade Namasethingi Okugcina Ukukhupha Kwamapoli Khabhonethi

- Inqubo Yokusika Izinyathelo Ngezinyathelo Yokuveza Amapuleti E-Polycarbonate Angenaphutha

- Iindlela Ezibalulekileyo Zokholoxa Xa Kuchithwa Iisheya Ze-Polycarbonate

-

Imibuzo Evame Ukubuzwa

- Izixhumanisi zikuphi okuhle ekugcineni izitiqa ze-polycarbonate?

- Kungani ukubamba isivinini se-RPM kubalulekile xa usebenzisa izihlalo zekhandela kumazitha we-polycarbonate?

- Ngani angakwenzani ukukhipha ngemva kokugcina polycarbonate?

- Izipi zokuphepha zikuphi ezilungile ekugcineni izitha ze-polycarbonate?