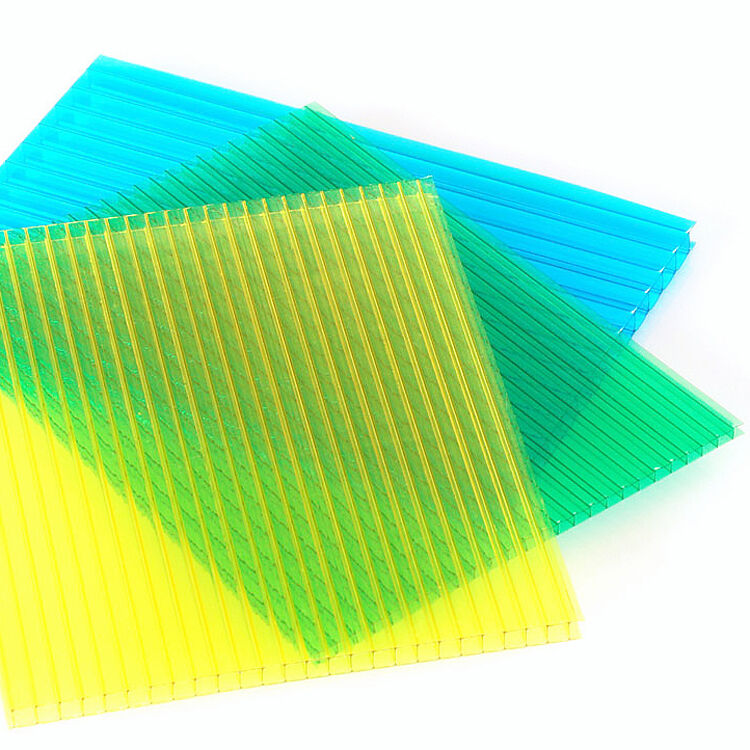

Zaɓi Mai Tsada Alatun Naka Shafukan Polycarbonate

Table Saws vs. Circular Saws vs. Band Saws: Zurfi, Kontin Tushen, da Kariyar Kari

Idan kun ka yi cutta mai tsakiyar kan kwayar polycarbonate, ba ababin ruwa suna iya kara kyau a cikin iyaka da samun doka mai sauƙi. Amma suna buƙatar taimako mai kyau ga abubuwan da ke haɗa su don zama ba tare da yin farfaru a lokacin cuttawa. Ababin ruwa na gabaɗayan suna aiki kyau ga alakari mai girman, saboda suna na jijiyar, amma akwai abin da ya kamata a tattauna game da agogo na palaggo. Yawan mutane suna ganin cewa raguwa zuwa akan 3,000 zuwa bisa 3,500 RPM yana taimakawa wajen kula da plastic ta hanyar karin shan gudu. Ababin ruwa na band suna aiki kyau da kwayoyi mai girman anta 8 zuwa 12 mm. Yin rawar palaggo tare da wayar shan gudu mai ƙarance ba tare da goyon doki yana nufin karancin cutta a doka. Ga wanda baya sha'awar aiki da wannan abun, ababin ruwa na carbide tipped tare da kamar 80 zuwa 100 doki kuma tattalin arziki na uku yana iya canza abu sosai wajen kula da shan gudu. Kuma karanci har ma babbar girman kerf. Idan kun rage shi ko da ƙasa 2 mm yana iya canza abu sosai a lokacin cuttawa kurve ko yin cuttowa mai tsakiyar ba tare da palaggo ta fito.

| Sakamako | Taswira | Tsarin Haka | Kwalitin Rashi | Mafi Kyau Don |

|---|---|---|---|---|

| Sawar Table | Tare daidai | Binciken | Kula | Cutoci mai tsawon sarari |

| Sawja Kula | Matsakaici | Muhimmanci* | Tare da kawai | Cutoci mai zurfi mai samun karfin |

| Sawar Band | Matsakaici | Tare daidai | Karatun karfi | Fusun karin girma/maƙili |

| *Yana bukatar tsarin RPM |

Jigsaws da CNC Routers don cut daga ciki ko cut na iko—Idan Farko Ya Sa Setup Time

Tsanya jigsaw mai tsanyawa akan 10 zuwa 14 tsanyawa per inch suna yi aiki kyau don yin kurve mai qaranci, amma dole ne suka da wani nufin kwalla domin kula shi ne mai iriri game da gudu. CNC routers za su iya zura zuwa sauran millimeter kan shape na iko, amma bari mu yi hakika, shigar da bayanai take extra time akan 15 zuwa 30 minti bayan kuma cut ya fara. Lokacin da kuke aiki ne akan abu da ke bukatar less than about five different cuts, yi amfani da kalamomin gida saboda suna fi kama. Bayan haka sai kuma, yi amfani da automated makes sense saboda CNC machines suna kula shi ne dimensional errors by roughly two thirds dibuwa da yin kansu ne saboda labarin da aka furta a Plastics Fabrication Journal. Kuma adahi ku ji downward cutting blades yayin da ke iya wannan, wadannan suna taimakawa wajen kula shekara ba su karɓe ba ko edges ba su karɓe ba yayin fara cut.

Karewa Hanyoyin Kulle da Saƙonni don Fashe Polycarbonate Mai Kyau

Diyar Tushen, Girman Sirri, da Mataki na Fashe: Karewa Kaluwar, Garkashawa, da Kariyar Ragira

Kada kai amfani da polycarbonate, carbide tipped blades da triple chip grind geometry bai sauki ba, suna bututu. Tsarin da aka yi na wannan haɓaka yana taimakawa wajen bauta chips yayin da aka fayyace kewayen cutta a tsakanin different tooth angles, wanda yana kama abubuwan da aka cut cooler yayin ayyukan. Don wadannan shafukan da ke mitatar da mita (ko 12.7 mm), nemi kerf mai tsawon 2.5 zuwa 3 mm. Kama da yawa yana tsoro da rashin fitowa koda idan bai shigar da feed speed a wani yanar gizo ba. Babban mutane sun sami nasara su kama da yadda aka shigar da feed rates a tsakanin 10 zuwa 15 feet per minute yayin aiki da 3 mm material. Yi pressure mai tsauri a gaba daya kai cut don kare da rashin abubuwa kamar melting don slow movement ko chipping yayin sudden speeding up. Kada materials ya tafi mitatar, kara kamar 20% karancin feed rate don kowace 3 mm da aka zama. Samun saukin saukin tool yana iya iya yin farko mai yawa, tools da suka configure suna iya kare da stress cracks kamar 40% kusa da regular high speed steel blades.

Ƙwararrun RPM da Kusurwar Hanyar Larabci (3—12 mm) don Kama da Ƙarin Ruwa

Daidaiton kusurwar gyara zai kasance ta hanyar larabci—ba hanya mai amfani da mesin kawai—don sarrafa ruwan baki. Farkon karanci suna barce ruwa sosai, sannan su ba da damar yin aikin kusurwa sosai; amma larabci mai girman zai richi kusurwa mai sauƙi don kula da sauya waje ko rukunin ruwa:

- shifofin 3—6 mm : 8,000—10,000 RPM tare da kusurwa mai sauƙi da daidaito

- shifofin 8—10 mm : 5,000—7,000 RPM tare da kusurwa mai daidaito da sauri

- shifofin 12 mm : 3,000—4,500 RPM tare da kusurwa mai sauƙi da baƙin kwana

Kada a yi amfani da cutar polycarbonate, muna sha'awar karancin RPM takamata 55% lokacin da muka kara dari 3 mm zuwa 12 mm saboda wannan abubuwa bai yiwu karfi darajar ruwa ba. Dole don ka duba irin chips dole yayi aiki a makon cutar. Chips mai zurfi da sauƙi zai nuna cewa duk abu suna tsaya. Amma idan ka fara ganin abun ciki mai zurfi ko mai doki, wato alamar hankali ce don masallaci. Yi amfani da uwar sama mai karfi don furta dust mai adalci kowanne lokacin da aka kwafi aikin. Irin debris wadansu suna tafi da kama ko guda, suna yi wajibi mai juzuƙi da kuma mai darajar ruwa wanda ke kara yanayin zunutawa. Wasu ma'aikatan halin fassara suna nuna cewa shiga ɗiyar uku na biyu daga bidiyo uku suna dabarce saboda an yi amfani da sauri da girman wurin da ba su daidai ba.

Tsarin Cutar Kadan-kadan don Cutar Polycarbonate Mai Sauƙi

Yadda Ake Linga, Nennar da Clamping Don Fara Fuskantar Warping da Misalignment

Samun sauyin magana ya fara kafin yadda dudum mai zurka ya wuce shi. Babban abubuwa, zaɓi maɓallin ruwa mai kyau da aka kwanke shi don aiki. Lokacin da kuka nuna inda kuke nema, always work directly on the protective film covering the sheet material. Yi amfani da markerin waka mai zafi wanda bai barci alama mai tsada ba, kamar yadda zan kawo wani waƙa ko markers da ke taka solvents saboda suna iya sumbatar sarari. Kunna lokaci don tabbatar da kowane girman bisa blueprints ko specifications. Kuskuren a wannan yanayi suna kamar yadda sun kasance ba za a iya gyara su ba kafin cuttin. Cuttawa masu tsunya suna bukatar fassarar kari. Daidaita abu mai tsauri kamar level aluminum ko ruler na steel mai tsafi akan hulullah halayen wa, sannan kun sauke shi cikin wurin sa. Kar a yi lafiya da gidajen plastic mafi sauƙi suna zumbata kafin pressure ya shigo a lokacin cuttin.

Wani hanyar sauke (clamping) ke cikin muhimmiyar rawa don ingancin ginya:

- Ka yi amfani da katako ko kuma ƙwanƙwasawa don ka sa matsin ya zama daidai kuma kada ka yi rauni.

- Sanya clamps a cikin 6 inci na yanke lineamma gaba daya a waje da hanyar ruwan wukakedon dampen vibration ba tare da hana tafiya.

- Tabbatar da cikakken tallafi a kan farar ƙasa, ba ta da lalacewa; duk wani abin da ya fi girma fiye da inci 2 yana da haɗarin lankwasawa, rashin daidaituwa, da kuma karyewar damuwa yayin ciyarwa.

Idan ba a yi amfani da shi sosai ba, zai iya sa a yi wasu raunuka, a yi wasu ɓarke-ɓarke a gefen, kuma a yi wasu ɓarke-ɓarke da ke faruwa bayan an yi hakan. Kyakkyawan clamping yana kula da kwanciyar hankali da kuma tallafawa daidaitaccen zafi dissipationduka tushe zuwa tsabta, m gefuna.

Matakan Tsaro na Muhimmanci Sa'ad da Ake Yankan Takardar Polycarbonate

Kāre Idanu, Fata, da Hanyoyin Hoto: Magance Ƙura Mai Ƙaranci, VOCs, da Fatsar Wuta

Khiya cuttawa da kayan polycarbonate, masu aiki suna face shararar kariyar lafiya daga cikin gargadi mai zurfi da aka haduwa a lokacin yadda ya ke tsaye. Wadannan gargadi sun kasance karanci 3 microns kuma suka haduwa da abubuwan mai zurfi da suka fi 150 daraja selsias, wadansu abubuwan na zurfi kamar styrene wanda zai iya kare lafiyar mutum a zaman kansa da hanyar tafiye-tafiyar zamani. Hanyoyin kariyar lafiya suna nebi a nan. Masu aiki suna bukatar ilmin gida mai tasiri (goggles) da aka kira ANSI Z87.1 domin kula da irin gargadi ta hannu don kare haɗin hannu da kayayyakin da aka fitowa bayan amfani da makini. Don karyar idan, alama N95 mai kyau da aka kara NIOSH zai sami kawai 95% na gargaji na sama, amma bai yi aiki ba idan bata fit daidai ko bata canza a lokacin da ake nuna ba. Bayani suna nuna cewa waɗansu mutane da suka aiki a wuraren da abubuwan na zurfi bata shigar ba suna ciƙin cin zarar koro. Tashi daga Occupational Safety Journal a 2022 ta bada laraba game da 34% karuwa a maɓallin idan a cikin masu aiki. Lokacin da yakiyar ta karu, karya mai zurfi suna bukatar saukunan karya. Kayan karya na VOCs na zurfi suna taimaka wajen kare waɗannan abubuwan na zurfi da suka fito sama. Wakilin da suka fara amfani da karyar lafiya ta musamman da matakan idan, matakan hannu, da matakan likita suna samun netta. Ga data daga Industrial Safety Council a watan karshe, wannan karya ta musamman taron adadin matattuwa ta ƙasa da kawai 72%. Wannan yana kake ban shaƙe karyar lafiya ba hanya karya amma wajibar kowane wanda ke aiki da kayan polycarbonate a matsayin masu aiki.

Tambayoyi Masu Yawan Faruwa

Wanne ne gudummawa masu iya cuttawa shekulla na polycarbonate?

Anfani da table saws yayi cutta mai zurfi, kuma cutta mai nisa. Anfani da circular saws yayi cutta mai nasara wajen kanin gari ko cutta mai tsawon girma, yayi cutta mai zurfi ko cutta mai yawa. Band saws yake aiki mafi kyau don shekulla mai zurfi da nisa masu itowa.

Mene ne ahayar RPM tare da amfani da circular saws akan shekulla na polycarbonate?

Yin la'urar RPM ke kama da muhimmiyar hana plastic na polycarbonate ta melt daga cikin harshen da ya haifarar friction bayan cutta.

Shin za a iya kare chipppin lokacin cutta polycarbonate?

Amfani da karafin carbide tipped blades tare da triple chip grind geometry, kamar haka kuma proper kerf width da feed rates, zai taimaka wajen kare chipppin.

Wane ne abubuwan kariya da aka wasuwa lokacin cutta shekulla na polycarbonate?

Zai fara bukatar amfani da goggles certified by ANSI Z87.1, nitrile gloves, da N95 masks don cutta safe, kamar haka kuma organic vapor cartridges don karyar kariya bisa VOCs.