Fahimtar Gama-Garin Abubuwa Na Polycarbonate Don Daidaita Mai Amain

Gama-gari mai tsoro na polycarbonate yana ba da damar daidaita—amma kawai idan aka gudanar da shi ta hanyar fahimtar takameltan tsuni da mekanikal. Tafalinniya (impact resistance) yana ƙasa 250 shekaru fiye zuwa ne kan glass, ta ba da damar canji tsari ba tare da kurkure, yayin da taimakon kewayen wayewa (flexibility) yana ba da amincewa ga darewa a cikin hududun musayar. Uku daga cikin gama-garuruwa masu alaƙa suna gudanar da daidaitar mai amain:

- Tackalwar Tackalwar , yin amfani da kayan aiki tsakanin –40°C da 120°C, yana ba da damar dare da tsuni bata kasance masa abin da ba zai iya dawo ba

- Karfin Tension (~70 MPa) ya tsaye adadin kurkure a lokacin daidaita

- Modulus ya kamata (2.4 GPa) yana nuna taswira a tsakanin kankanta da kyakkyawan zartarwa - masu mahimmanci ga ganin saukin zarta da iyaka

Khiyar da keke aiki da kayayyaki, akwai wani hudu mai sauƙi na kewayawa mai nau'ikan 150 kadan kama da girman shafin. Wannan taimakawa wajen daina waɗannan tsararru mai sauƙi suka samuwa akan nisa don hanyar da aka ambata sauri. Idan mutum yin bauta zuwa baya da wannan ma'auni, zai iya sabunta babban gyara kayan aikin ita ckin. Don ayyukan kewayawa ta hanyar ruwa, amfani da tsawon yanayi daga cikin daraja 150 zuwa 190 Celsius suna muhimmi. Idan an karami mai karanci, za a magana da alamar yawa ba za su iya girma don bayar da wurin gudanar da kyau ba. Amma idan ka tafi baya 190, za a fara kwatanta alamar da yawa. Girman kayan aikin yana iya taka rawarin nan. Shafuka masu girman suna buƙatar ruwa mai yawa ko hudu mai girman baya ga suƙuru. Wannan tariha taimaka wajen daina rarruwana suka faskotar a lokacin ayyukan yi kuma sako kayan aikin ya sake hada da nisa a karkashin bayyane.

Kewayawa ta Sanya Polycarbonate: Lokacin Da Tana Aiki da Kuma Hudunun Muhimmi

Ana amfani da kewayar sanyi ko'ina a matsayin hanyar da ke kasa, wadda ba shi da kayan aikin kamar yadda ake so don kewayoyi masu sauƙi da aikace-aikacen da ke ƙasa—idan aka yi amfani da hanyoyin amfanin kayan aikin. Tana taimakawa a kuma kyakkyawa da ke zurfin polycarbonate a tsawon girma, bai tsammanin kewayar harshen ba, kuma yana nuna cewa amfani da hanyoyin kiyaye kayan aikin yana da mahimmanci don kiyaye kayan aikin.

Ƙarƙashin Tafini na Kewayar Kewayar da Kuma Kiyaye Kayan Aikin a Duniya Mai Tsanma

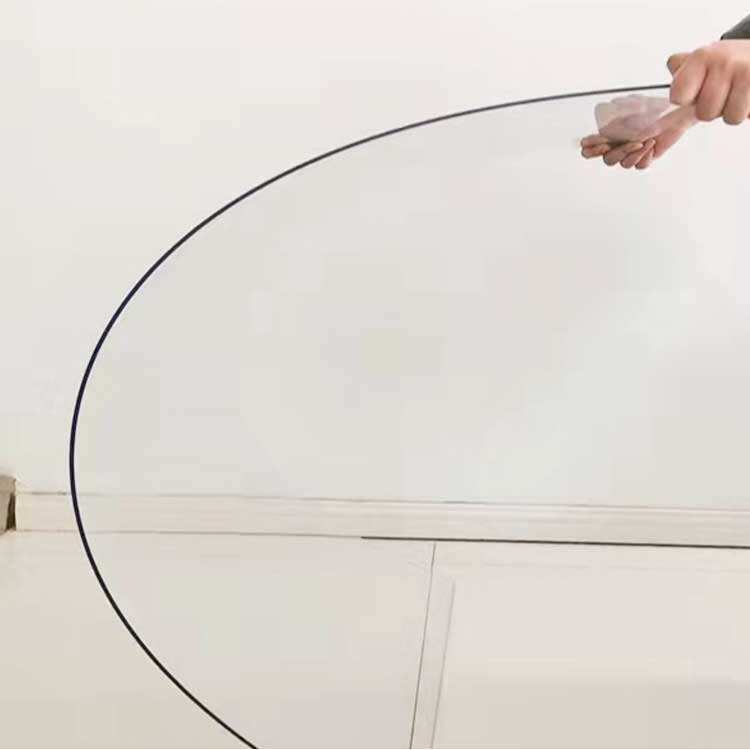

Yawancin jagororin masana'antu suna ba da shawarar kiyaye radius na lankwasawa aƙalla sau 150 na kaurin takardar. Wannan yana nufin ga wani misali 3mm m abu, muna bukatar m radius na kusa da 450mm. Idan aka yi watsi da waɗannan iyaka, za a sami matsi fiye da yadda polymer zai iya jimrewa, kuma hakan yakan sa a samu ƙananan fasa ko kuma a fasa kayan gaba ɗaya. Ga manyan takardu sama da 6mm, yawanci akwai ɗan ƙaramin bazara bayan lankwasawa, don haka masu fasaha yawanci suna buƙatar lanƙwasawa kusan digiri 20 zuwa 40 bayan kusurwar da ake so. Kuma sanyi kafa bends kamata ba su wuce yawa 90 digiri ko dai idan muna so mu zauna lafiya a cikin na roba kewayon da hana wadanda m m deformations cewa babu wanda yake so ya magance daga baya.

Tsarin Layin Cold Lines Mafi kyawun Ayyuka don Hana Microcracking da Delamination

Kayan aiki na ainihi da kuma sarrafawa ba su da wata ma'amala don tsabta, madaidaiciyar layi:

- Zaɓin kayan aiki : Alkawali mai sharafan karami suna kula da alhakin cikin sauyin karami; alkawali maras sharafa suna haifar da rashin tsawo a cikin alhaka kuma suna fara microcracks

- Sanya sarufa : Sarufan cut must be smooth and free of nicks or burrs—stress-concentrating flaws that accelerate crack propagation

- Gudanar da springback : Don 30° final bend, form 50°–70° initially and allow 48 hours for stress relaxation before trimming

- Daidaiton amfani : Avoid cold line bending for UV-coated, safety-critical, or high-impact applications—residual stress remains locked in and compromises long-term performance

Always validate parameters on scrap material before committing to production.

Heat Bending Polycarbonate: Controlled Thermal Forming Techniques

Optimal Temperature Range, Pre-Drying, and Avoiding Thermal Degradation

Samun sauyin bincike daga natsu na yanki ke richa gaskiya a cikin tsarin natsu. Babban kayan kaya suna aiki kyau lokacin da ake natsawa a tsakanin kusan 155 da 190 daraja Selsiyus. Idan an kara natsu ka fi 150, ba za a iya wakilta polycarbonate ba. Amma idan zaka karya 220, za a fara kura a matsayin molekular, wanda ya nuna abubuwa kamar bubu, canjin launi, da kayan natsu mai tsutsuwa bangare da ba za ta iya karɓar kuskure ba. Karɓar shafuka a baya ta hanyar natsu na kusan 120 daraja don sauƙi zuwa zuwa huɗu sa’i ba za ta kasance buƙatar ajiye ba. Dukkanin ruwan da suka fito suna canza zuwa ukuwa yayin natsawa, suna kirkirar albarkatu na ukuwa da kuma rashin kyau na surface wanda babbu ne so. Bayani na sarrafa tattalin arziki suna nuna cewa shafukan da ba a karɓe su ba suna kuskuren kama da mituna a karkashin ayyukan kirkira. Don natsu mai kyau a cikin shafukan maƙarfi, convection ovens sune abin da ake amfani da su, amma yankunan sasa bisa ne amfani da infrared panels. Kada kare duba natsu na asali ta hanyar alkarbar pyrometer, saboda nuna oven na iya samun farko na plus ko minus uku daraja. Wancan nau'in farko yana iya maimakon dukkan farko lokacin da kake kwarewa sauyin bincike kyau a karkashin batch zuwa batch.

Hot Line Bending vs. Uniform Heating: Zaftanin A selecting for Precision Bending Polycarbonate

| Tarehe | Mafi Kyau Don | Tattabara | Abubuwan Gaskiya da Yawa |

|---|---|---|---|

| Hot Line Bending | Kwana, kwallon kwana a kan shafukan wata | Heated wire/strip heaters | Yi amfani da 175—190°C ta hanyar kwallon kwana; yadda zai sa radii su dace zuwa 100– thickness tare da karancin karfi |

| Uniform Heating | Shakalolin 3D masu yawa da kwallon kwana | Convection ovens | Pre-drying is mandatory to preserve optical clarity and structural homogeneity |

Zaune mai dubawa suna aiki da zurfi saboda suna kaucewa ne akan karewa kawai wadanda suke bukata, yayin da keji duk wani abu na sauran yanayi. Wannan hanyar yin aiki tafiya ga ganin alamar daidai, wacce ke iya canza dukkan abu yayin aiki kan kayan takama, ko kuma halartawa. Yayin amfani da gajeren cewa, mafarkaɗauke suna ba mu zama’azaman yawa amma suna buƙatar ilimi da wasu mahamali don samun siffar shi. Hikima shine harba nozul ta hanyar da aka ce kusan 10 cm kusa da sekondi, kuma rufe shi da kusan 10 zuwa 15 centimeter daga abin da muka ce waɗa muke kawo, don haka babu abu za a sarrafa. Nawar jig da muke amfani da shi kuma yana iya canza abu sosai. Mafarkaɗauke suna iya tallafawa abubuwan da aka tsaya da kwayoyin aluminiyum domin kawowa daidai, yayin da kayan silicone suna kariyan saufin kasa daga kututtuka. Mafarkaɗauke suna ganin abin da ya farin ciki ne sai dai karɓe abubuwan da aka ce kusan 7 zuwa 10 digiri bisa wanda suke so sun dace, saboda abubuwan suna koma kusan karo bayan karɓawa. Suna gaba da anneling, wanda muke buƙatar rage idanun abu. Kawowa da kusan 125 digiri Silishiya kusan mita'ar nan kusa da kowace uku millimeters yana aiki da kyau a karkashin dukkan ayyukan.

Tambayyar Bayan Kwatanta da Kiyaye Aiki a Nobi

Gudanarwa Kwatanta, Kwatanta Bayan Kwatanta, da Gudanarwa Mai Nobi

Lokacin da ke kaɗawa, kayayyakin polycarbonate suna zai nuna kaɗawa babu daga cikin 2 zuwa 5 daraja saboda sifaɗɗan hankali na molekulai. A yaukyau amsawa? Kaɗawa ta hanyar tare da gama-gari ya dace wajen nan. A kalmomi masu amfani, lokacin da ke tsere abubuwan waɗannan, yi rawar daga cikin 15 zuwa 20% karƙashin abin da ake buƙata. Don duk kaɗawa mai tsaro da yawa da fi 90 daraja, akwai hanyar mataki mai muhimmanci daya za a iya nuna. Ana buƙatar annealing na kwallo a tsawon 125 zuwa 135 daraja Selsiyus. Tsawon lokaci yana dogara akan kwayoyin too - a kalmomin umarni, ba ajiye dari zuwa biyu awa don kowace millimeterin 3 na kayan aiki. Me kake tafi da duk wannan rashin rahama? Wannan ayyukan kwallo eneku ya kara shigowa mai 내 daga cikin 70 zuwa 90%. Ya kashe waɗannan cututtuka mai zurfi da ke fitowa a yankuna da aka yiwa ga tasowa ko ramaran kasa. Sai kuma, ya taimaka wajen koyo wani look mai zurfi wacce ke mahimmanci ga abubuwan da ake amfani da su a yankun duniya.

Ana buƙatar annealing yana dogara akan kwayar too da aiki:

| Rangin Tsohon | Sharrarin Annaya |

|---|---|

| < 3mm | Za a iya amfani da shi don duka ko kasa ta hannu wadanda bai ke yawa ba |

| ≥ 3mm | Yake wajib wa tsangewa, abubuwan da ke mahimmacin sarrafa, ko kayan da ke tsofaffa sama |

Ya kamata sa'an karorin bayawa yayin tsawon sashin gini—ba kyau karshen 5°C kowace minti—to barke cikin sa'annin haɗin mollar. Bayanan hankali suna nuna cewa kayan da aka annaya suka barke 98% stabilitin girma zuwa zuwa 5 shekara ta hanyar tafiƙar UV da tsawon karɓar zango, saboda haka ne 76% ga kaya mara annaya .

Tambayoyin da aka fi tambaya game da Tsangewar Polycarbonate

Wane ne kudaden ƙimaɗin gwadawa don lalatawa polycarbonate?

Polycarbonate yana tsaya da alaka a tsakanin –40°C zuwa 120°C don lalatawa mai sanya. Don lalatawa mai neri, kunna shanuwar tarihin 150°C zuwa 190°C don waya daga kashin karfi.

Yaushe yana iya tasowa kan proses mara lalatawa?

Kwataturen sheets na polycarbonate suna buƙatar zafi ko radii na lalatawa masu girma karƙara ga wadanda su farfu. Wannan taimakonai wajen yanke jaraboci daga sauya kuma kiyaye sauya mai kyau.

Shin lalatawa mai sanya ta hanyar layi sunyaya don duk iyakokin polycarbonate?

A'a, ba shine don sha'awar UV, abubuwan da ke cikin danger, ko applications masu cin zarafi saboda kansun stress.

Me ya kamata a ruwa komai a cikin proses mara lalatawa mai neri?

Ruwa komai a makamashi takwas 120°C ga biyu zuwa hudu awa yin bauta ruwa wacce za ta zama abubuwa irin damu, ta haɗa maɓakiyar doki da abubuwa mai sharuwa a lokacin neri.

Teburin Abubuwan Ciki

- Fahimtar Gama-Garin Abubuwa Na Polycarbonate Don Daidaita Mai Amain

- Kewayawa ta Sanya Polycarbonate: Lokacin Da Tana Aiki da Kuma Hudunun Muhimmi

- Heat Bending Polycarbonate: Controlled Thermal Forming Techniques

- Tambayyar Bayan Kwatanta da Kiyaye Aiki a Nobi

- Tambayoyin da aka fi tambaya game da Tsangewar Polycarbonate