Understanding Polycarbonate Material Properties for Safe Bending

Polycarbonate’s unique mechanical properties enable successful bending—but only when guided by precise thermal and mechanical understanding. Its impact resistance is approximately 250 times greater than glass, allowing controlled deformation without shattering, while its inherent flexibility supports shaping within defined limits. Three interrelated properties govern safe bending:

- Thermal stability, maintaining structural integrity between –40°C and 120°C, enables heat-assisted forming without irreversible degradation

- Tensile strength (~70 MPa) resists fracture under bending stress

- Flexural modulus (2.4 GPa) determines the stiffness-to-bendability balance—critical for predicting springback and radius feasibility

When working with materials, there's a minimum cold bending radius that usually equals about 150 times the sheet thickness. This helps prevent those tiny cracks from forming on the surface because it limits how much strain gets applied. If someone tries to bend beyond what this standard allows, they risk causing serious damage to the actual polymer chains in the material itself. For heat bending applications, maintaining temperatures between 150 degrees Celsius and 190 degrees Celsius is critical. Go too low and the molecules won't move enough to allow proper shaping. Push past 190 though and things start breaking down thermally. Material thickness plays a big role here too. Thicker sheets need either significantly more heat energy input or bigger bending radii compared to thinner ones. This approach helps keep layers from separating during processing and makes sure the material springs back predictably after being shaped.

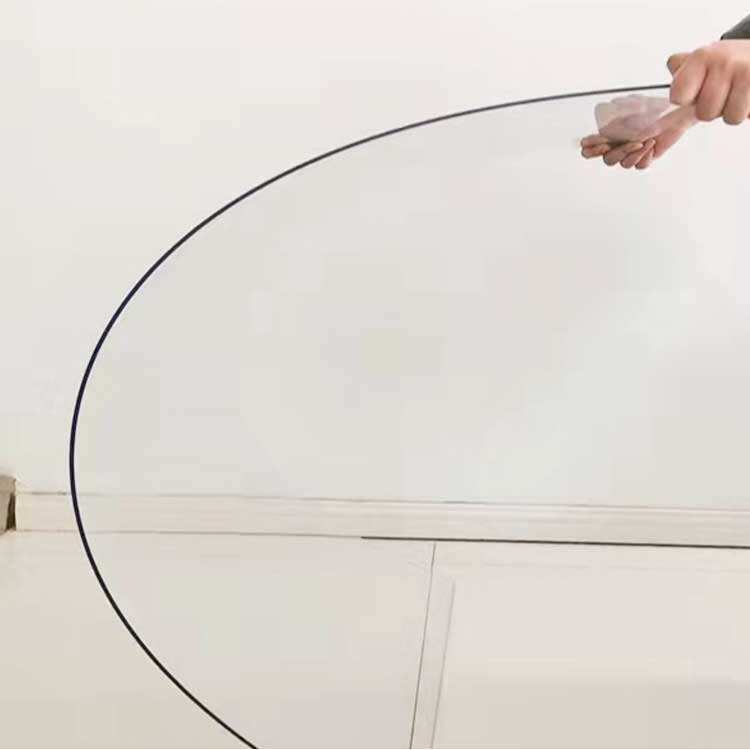

Cold Bending Polycarbonate: When It Works and Critical Limits

Cold bending is a cost-effective, equipment-free method ideal for simple arcs and low-volume applications—provided material limits are respected. It relies entirely on polycarbonate’s room-temperature ductility, not thermal softening, making adherence to mechanical thresholds essential for structural integrity.

Minimum Bending Radius by Thickness and Real-World Structural Tolerance

Most industry guidelines recommend keeping the bend radius at least 150 times the sheet thickness. That means for a standard 3mm thick material, we need a minimum radius of around 450mm. When these limits get ignored, stress builds up past what the polymer can handle elastically, which often leads to tiny cracks forming or even complete fractures in the material. For thicker sheets above 6mm, there's usually quite a bit of springback after bending, so technicians typically have to bend about 20 to 40 degrees extra past the desired angle. And cold formed bends shouldn't go much beyond 90 degrees either if we want to stay safe inside the elastic range and prevent those annoying permanent deformations that nobody wants to deal with later on.

Cold Line Bending Best Practices to Prevent Microcracking and Delamination

Precision tooling and disciplined handling are non-negotiable for clean, durable line bends:

- Tool selection: Sharp-edged dies concentrate force cleanly along the bend line; dull tools cause uneven stress distribution and initiate microcracks

- Edge preparation: Cut edges must be smooth and free of nicks or burrs—stress-concentrating flaws that accelerate crack propagation

- Springback management: For a 30° final bend, form 50°–70° initially and allow 48 hours for stress relaxation before trimming

- Application suitability: Avoid cold line bending for UV-coated, safety-critical, or high-impact applications—residual stress remains locked in and compromises long-term performance

Always validate parameters on scrap material before committing to production.

Heat Bending Polycarbonate: Controlled Thermal Forming Techniques

Optimal Temperature Range, Pre-Drying, and Avoiding Thermal Degradation

Getting good results from heat bending requires careful temperature management. Most sheet materials work best when heated between around 155 and 190 degrees Celsius. If temperatures drop below 150, polycarbonate just won't bend properly. But go past 220 and things start breaking down at the molecular level, which shows up as bubbles, color changes, and weaker material that can't take impacts anymore. Drying the sheets first at about 120 degrees for two to four hours isn't optional really. Any leftover moisture turns into steam while heating, creating those pesky internal air pockets and surface flaws nobody wants. Industry studies indicate that sheets that haven't been dried properly end up failing almost half the time during shaping processes. For even heating across large sheets, convection ovens are usually the way to go, but smaller areas might need infrared panels instead. Always check the actual surface temp with a contact pyrometer though, because oven displays can be off by plus or minus five degrees. That kind of variation makes all the difference when trying to get consistent results batch after batch.

Hot Line Bending vs. Uniform Heating: Tool Selection for Precision Bending Polycarbonate

| Method | Best For | Equipment | Critical Considerations |

|---|---|---|---|

| Hot Line Bending | Sharp, linear bends on thick sheets | Heated wire/strip heaters | Maintain 175—190°C precisely at bend line; enables radii down to 100– thickness with minimal thinning |

| Uniform Heating | Complex 3D shapes and compound curves | Convection ovens | Pre-drying is mandatory to preserve optical clarity and structural homogeneity |

Hot line bending works really well because it focuses on softening just the needed areas while keeping everything else rigid around it. This method is great for getting those fine details right, which makes all the difference when working on things like building glass installations or creating protective covers. When making prototypes, heat guns give us lots of options but they require some skill to handle properly. The trick is moving the nozzle constantly, maybe around 10 centimeters per second, and holding it about 10 to 15 centimeters away from what we're heating so nothing gets burned. What kind of jig we use matters a lot too. Aluminum molds help things cool down faster and make sure our shapes stay accurate, whereas silicone padded setups protect surfaces from getting scratched up. Most people find it helpful to bend materials a bit extra, somewhere between 7 and 10 degrees beyond where they want them to end up, since materials tend to spring back slightly after bending. Then comes the annealing part where we need to relieve stresses in the material. Heating at around 125 degrees Celsius for roughly half an hour for every three millimeters thick seems to work pretty consistently across different projects.

Post-Bend Stability and Long-Term Performance Assurance

Managing Springback, Overbending Protocols, and Stress-Relief Annealing

When bent, polycarbonate materials tend to spring back about 2 to 5 degrees because of their molecular memory properties. A common solution? Calibrated overbending works well here. Basically, when forming these parts, aim for angles that are around 15 to 20 percent beyond what's needed. For any structural bends exceeding 90 degrees, there's another important step worth mentioning. Thermal annealing becomes necessary at temperatures between 125 and 135 degrees Celsius. The duration depends on thickness too - generally speaking, allow 1 to 2 hours for every 3 millimeters of material. Why go through all this trouble? Well, this heat treatment actually cuts down internal stresses by roughly 70 to 90 percent. It stops those tiny cracks from forming especially in areas subject to constant movement or vibrations. Plus, it helps maintain that clear look so important for transparent components used in various applications across industries.

Annealing necessity depends on thickness and function:

| Thickness Range | Annealing Requirement |

|---|---|

| < 3mm | Optional for cosmetic or non-load-bearing bends |

| ≥ 3mm | Mandatory for load-bearing, safety-critical, or outdoor-exposed parts |

Post-formation cooling must be gradual—no faster than 5°C per minute—to lock in stabilized molecular alignment. Field data confirms that properly annealed components retain 98% dimensional stability after 5 years under UV exposure and thermal cycling, versus just 76% for non-annealed bends.

FAQs on Bending Polycarbonate

What are the thermal limits for bending polycarbonate?

Polycarbonate maintains structural integrity between –40°C and 120°C for cold bending. For heat bending, maintain temperatures between 150°C and 190°C to avoid degradation.

How does thickness affect the bending process?

Thicker polycarbonate sheets require more heat or larger bending radii compared to thinner ones. This helps prevent layers from separating and ensures predictable springback.

Is cold line bending suitable for all types of polycarbonate applications?

No, it is not suitable for UV-coated, safety-critical, or high-impact applications due to residual stress.

Why is pre-drying important in the heat bending process?

Pre-drying at around 120°C for two to four hours removes moisture that could turn into steam, creating air pockets and surface flaws during heating.